Dust Collecting Unit

Product Details

Technicial Specifications

Other products

About the Company

Contact

Our ADC ATEX Dust Collectors feature advanced cartridge filter technology with a Pulse Jet automatic cleaning system. These units provide clean air, extended filter life, and a compact housing design. They are designed in accordance with EN and NFPA standards.

Key Features:

- Plug & Filter: Easy installation and maintenance.

- Explosion Resistance: Ensures safety in hazardous environments.

- Energy Saver: Efficient operation reduces energy consumption.

- Durable Construction: Made from minimum 5 mm thick HRP St37 steel sheet, available in SS versions.

- Tailored Solutions: Multiple options including Sliding Butterfly Valve, Double Butterfly Valve, BIBO (Bag In Bag Out), and Continuous Liner Discharge.

- IIoT Integration: Enhanced monitoring and control capabilities.

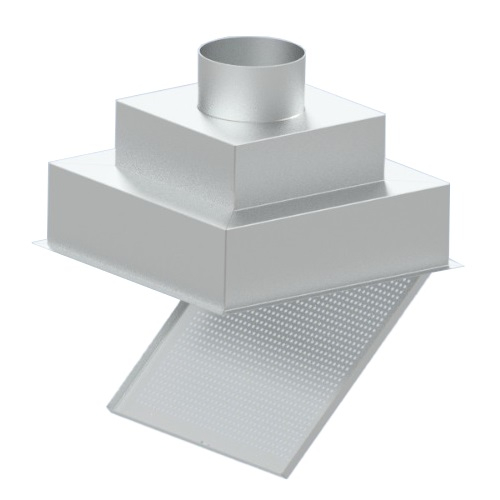

The Body is constructed from a minimum 5 mm thick HRP St37 steel sheet (SS versions are available), integrated with bolts and nuts. The grill structure of the dirty air inlet will direct the large particles to the hopper and the filters will be prevented to face large particles.

Dust bins have a mechanism that will have easy maintenance. Bag discharge together with the dust bin discharging makes it easier.

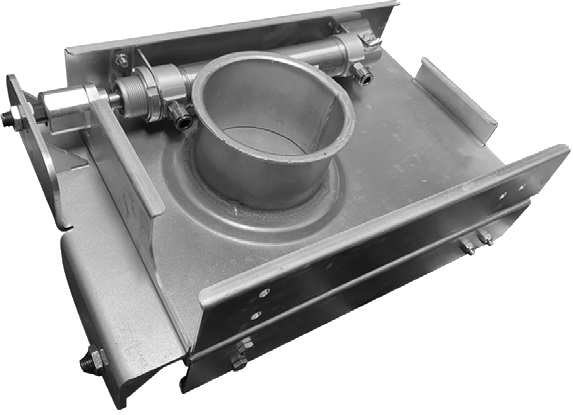

A sliding valve helps to cut off the connection between the dust bin and the discharge connection of the bunker.

A double Sliding valve helps to cut off the connection between the dust bin or discharge connection of the bunker while supplying a continuous discharging to the Big Bag.

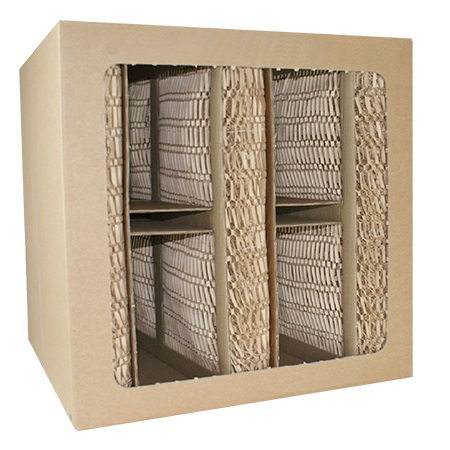

Together with the BIBO (Bag in Bag Out) bag safe change personnel will not be exposed to any dust while filter change and the dust disposal. Bag connections are made at the service doors where the filters are changed and dust bin connections for the dust disposals. The service door opening mechanism is designed to decrease the service lost time while opening and closing as low as below 30 seconds without using any tool, bolts, or nuts.

It is a self-folded bag structure that reduces charging times by providing continuous change. Position sensor information, automation information, sealed bucket system with ATEX pistons.

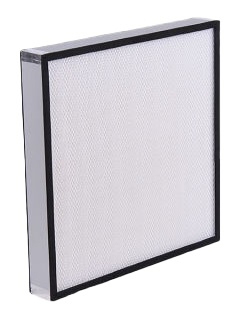

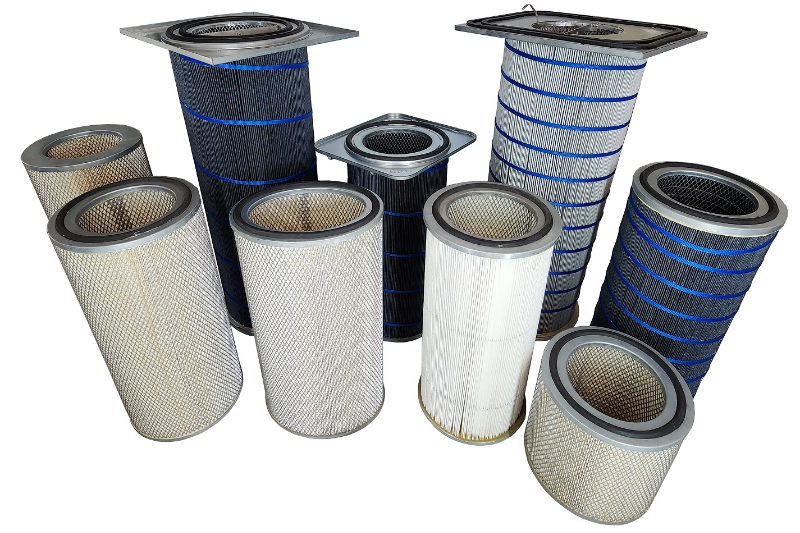

Cartridge filters are the heart of the ADC. Electroconductive cartridge filters can work continuously at 80°C. All filter media have a minimum efficiency of F9 EN779 2012 / MERV 15. Surface load causes acceptable dust cake over the filter surface which increases the filtration efficiency. These kinds of filters have 10 times higher efficiency than causal filters. Surface loading prevents the blockage of the filter and makes the removal of the dust cake easier. In order to comply with the protection in an environment with a high risk of dust explosions, a filter with conductive media which is flame retardant (F1 acc. to DIN 53438) provides superior filtration performance. Filters not only collect dust particles but also work as an active component of a protection system against dust explosion. Filter helps for preventing spark injection in the dust collector

Airprocontrol Endüstriyel Klima Tic. A.S.

APC – AirProControl has been established to supply Professional Air Controlling Devices and Services, especially for industrial environments. Air Pollution Control and supplying clean & safe working areas while keeping production process air at controlled leveled always. These main devices are dust collectors, vacuum collectors, wet filters, gas scrubbers, silica gel dehumidifiers, special design industrial air handling units, process dehumidifiers, etc.

Products that are built-in confidence more than 20 years of experience and references together with production under ISO9001, ATEX regulations & NFPA legislations.