Product Details

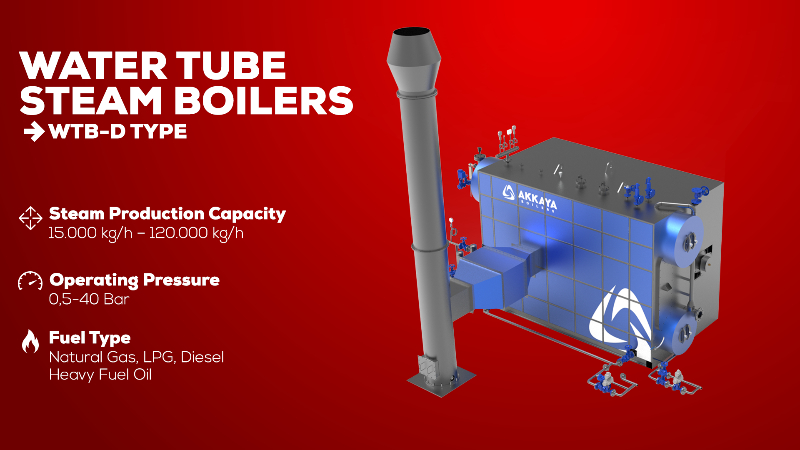

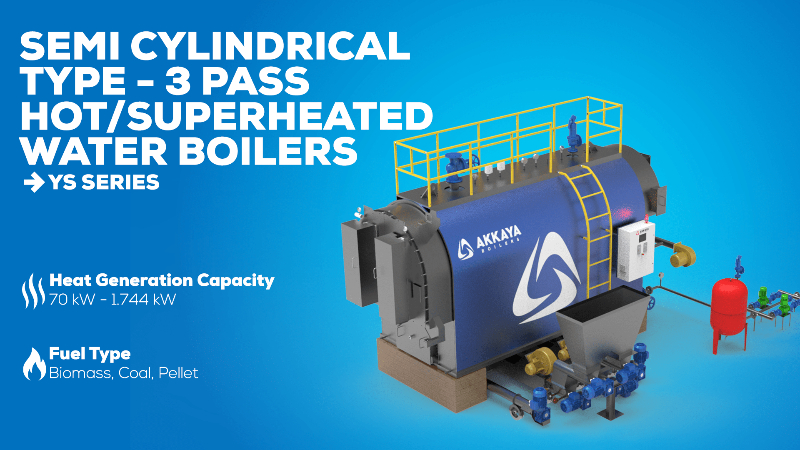

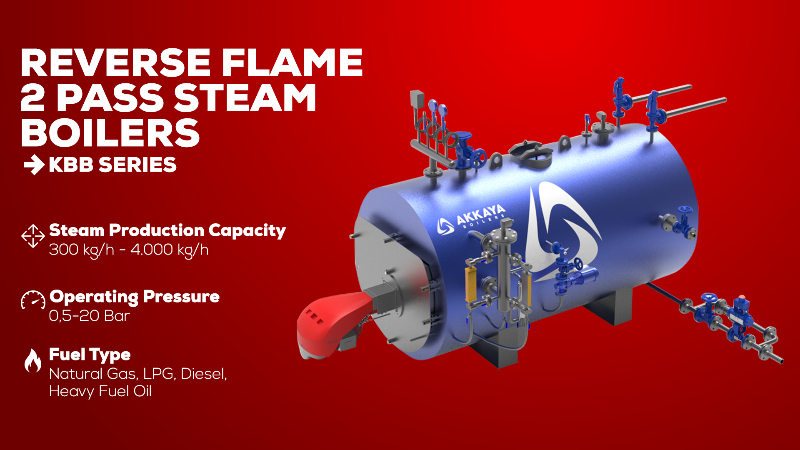

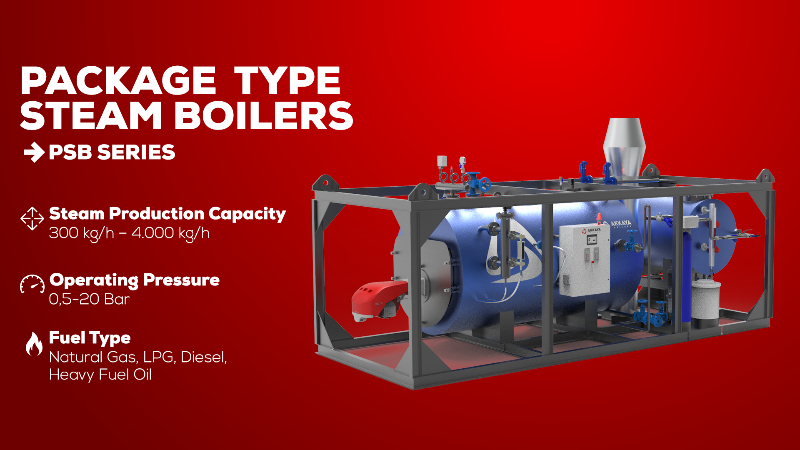

Technicial Specifications

Other products

About the Company

Contact

• Hybrid type (water tube front burner, rear smoke tube) design allows low flue gas temperatures and high efficiency.

• The water tubes forming the front furnace are produced in the form of membrane pipe wall in an automatic pipe boiling machine and are bended with high precision in an automatic membrane wall bending machine.

• Thanks to the front furnace design, combustion is completed wholly and efficiently and provides fuel saving.

• According to the type of fuel to be used in the boiler and customer request, suitable for use as a combustion system with the “Automatic Fuel Feeding Stoker“,”Water Cooled Vibrating Grate” and “Manual Grate” options.

• With appropriate combustion systems, wood, woodchips, charcoal, olive pomace, pellets, briquettes, almond husks, walnut husks, hazelnuts husks, pulps of fruit, seed husks, chicken manure and pellets, bamboo, corn cobs, forest scraps etc. many types of fuel can be used efficiently and with low emissions values. The fuel flexibility provided by the design of combustion systems keeps operating costs constantly low.

• Optional systems such as “Automatic Ash Removing System“,”Automatic Ignition System” and “Automatic Tube Cleaning System” that provide operator-free operation, allow efficient, stable and fully automatic controlled operation.

• The flue gas filter selected in accordance with the fuel characteristics (“Multicyclone“, “Cyclone“, “Wet Flue Filter“, “Bag Filter“) ensures that the emission values are kept below the permissible limits.