Radiator

Product Details

Technicial Specifications

Other products

About the Company

Contact

• 1 million meters of panel radiator production capacity per annum

• Cutting edge production lines

• Water-based Premium paint, nano-technology surface coating processes along with epoxy polyester powder

paint

• High stocking and fast delivery

• Domestic and international product certifi cation

• Test pressure of 13 Bar

Green Technology

Nanotech surface fi nishing chemicals create a thin but hard coating over the surface. Unlike the old types of coating, it features zirconium (Zr) instead of iron (Fe) and zinc (Zn). The coating formed after nano-ceramic chemical treatment features high adhesion strength. It offers corrosion resistance above the performance of iron-phosphate technology, approaching the performance of trication zinc phosphate.

• Eco-friendly coating

• Does not contain heavy metals, toxic waste and other hazardous substances.

• Low waste water.

• One of the types of surface fi nish with multi-metal surface fi nishing.

Radiators are painted with wet paint immersion technique after nanotech surface fi nish, electrostatic powder paint for fi nal coat and packaged for delivery to end-user

Airfel panel radiator production, coil slitting line, slitting process, the formation of actual steel coils and sheets panel and convectors presses spot welding line, formed by bringing together welding and spot welding and seam welding. Panel leaves, panel presses are produced automatically. Convector plate, is produced in the convector press.

Airfel panel radiators feature ideal pitch ranges and suitable convector size, allowing 1 linear meter of Type 22 PKKP 600 series radiator produces 1.718 watt of heat. (This value is according to 75/65/20 °C regime values and approved by HLK.)

With 10 bar operating and 13 bar test pressure, Airfel panel radiators are safe and resistant to high pressure

Daikin Isıtma ve Soğutma Sistemleri Sanayi Ticaret Anonim Şirketi

Having been active in Turkey through its distributors since 1978, Daikin has become the most powerful players of industry with the acquisition of Airfel in July 2011.

Today among other brands, Daikin has the widest product range in Turkey in heating, cooling and ventilation fields.

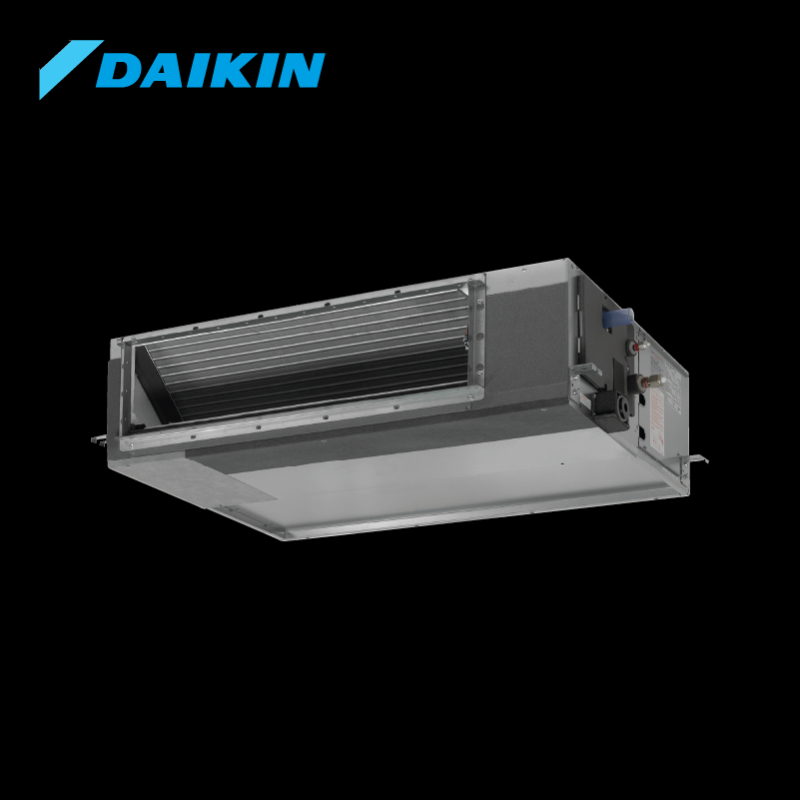

Daikin Turkey manufactures Daikin and Airfel branded air conditioners, combi boilers, panel radiators, fancoils, air handling units etc. with cutting edge technology to offer total air conditioning solution to meet different customer needs.

In production facilities of Daikin located in Hendek, Sakarya with LJ 2.000 m2 closed sarea on 100.000 m2 space; along with Airfel branded units, Daikin branded products started to be manufactured.

Split Air Conditioning Production Line, Air Handling Unit Production Line, Fan Coil Production Line, Combi Boiler Production Line, VRV Production Line / Hendek Sakarya