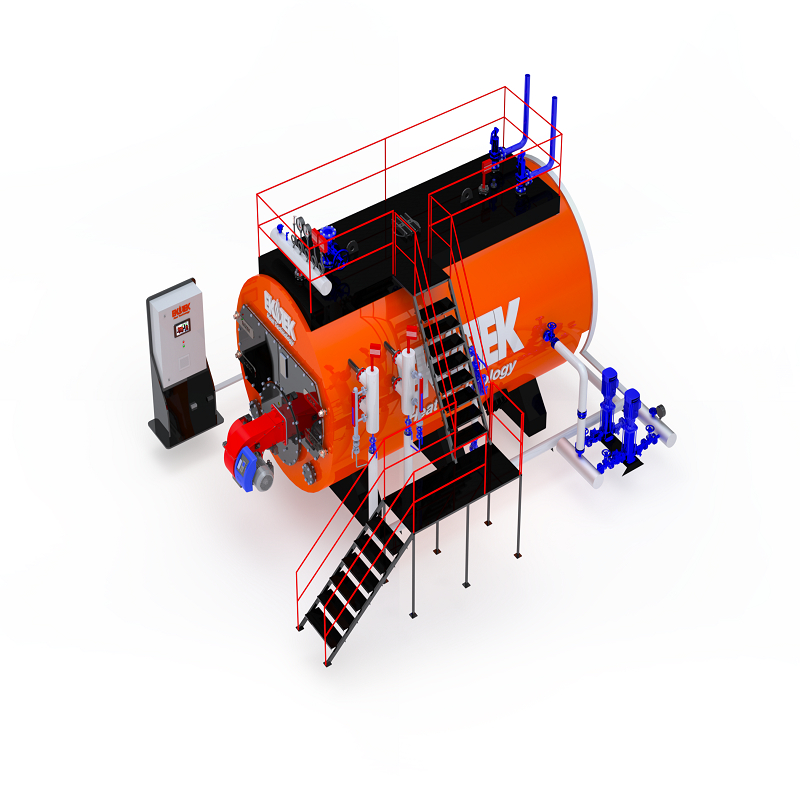

HYBRID SERIES

SOLID FUEL HIGH PRESSURE STEAM BOILER

2.000 kg / h - 25.000 kg / h steam production capacity 3 - 25 bar operating pressure

Chain grate, rotating grate Biomass Steam boiler Special series

If you want to be in control, you should definitely see our optional options. Control your power with Ekotek technology. With optional options; Plc Touch screen controlled, Modbus RTU (Remote Terminal Unit (Rtu) is completely in your control.

· it has the safest boilers in Turkey with 5 different safety devices.

• Boiler types with water pipe and flame smoke pipe in the same body HYBRID BOILER is created.

• Water tube primer mounted on chain grid or stoker furnace required as a result of detailed and precise calculations It is manufactured at a height and a large-volume combustion chamber is created on the chain or movable grate. Radiation heat boiler with Scotch type boiler with flame smoke pipe is connected with water collector pipes.

• Large volume combustion chamber, flame length in solid fuels, flame radiation, maximum gas and heat generated by combustion is required to be.

• Second (secondary) module Flame smoke tube boiler has two passes. in order to obtain maximum efficiency for the required Capacity has been designed.

• The volume of smoke decreasing as the temperature drops, from the boiler It is designed to pass at optimum speeds. In the boiler the passage paths of the flame are kept long a large part of the heat energy remains in the boiler and steam used in production.

• With larger vapor volume, the system can react instantly thanks to the primary pipe with water pipe. Flash steam production is provided.

• Exchange of the pipes of the boiler with a flame smoke pipe; Front and back The covers can be changed very easily by opening.

• Hybrid Steam Boiler steams all the calories of the fuel burning.maximum fuel value as it fully reflects in the production process it is possible to obtain as much heat and turn it into steam.

• You can use Hybrid Steam Boiler in approximately 82% -86% efficiency.

• There are bluff and flanged cleaning in lower collectors.

• While calculating the boiler heat load, the optimum heat load is given to the boiler heating surface area.

• Due to its hybrid feature, standard gas / liquid fuel steam boiler

• The inadequate heat transfer surface encountered during the combustion chamber solid fuel applications completely eliminates the problems.

• Extra heating surface is completed with water and flame pipe system. solid fuel burning efficiency is much higher in 3 Pass Scotch Type Boilers than solid fuel burning. It provides high performance in intense and continuous working conditions and sudden steam traction with its wide water and steam volume.