Product Details

Technicial Specifications

Other products

About the Company

Contact

NORMAL WORKING CONDITIONS

Nominal pressure : PN 35 up to diameter 54 and PN 25 from diameter 64

Temperature : -100 ºC min + 250 ºC max

Fluid : suitable for group 2 according to art. 9 Directive 97/23/EC (P.E.D.)

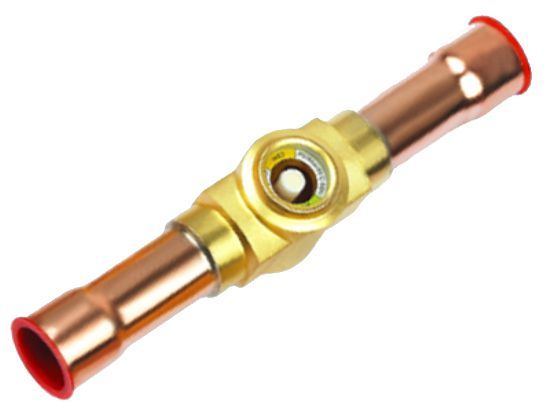

CONSTRUCTION

Manifacturing in accordance to Directive 97/23 /EC (P.E.D.) requirements. Lett vibration absorber is made from stainless steel with copper DHP end fittings. All weldings, included copper/stainless steel, are made by TIG or laser systems.

Being brazing-free, it is possible to braze the end fittings to the pipe system without any overheating risk to the lett itself.

EMPLOY

Lett vibration absorber is used to avoid the vibrations induced by the compressor. It also reduces noises and can compensate smaller inner displacments. Furthermore, its unique speciality allows vertical installation too. The possibility of water condensation in the lower side has been eliminated, therefore, no problem even at temperatures below 32 ºF (0 ºC).

INSTALLATION

User must be aware that lett cannot absorb torsional and axial stresses, either in compression and extension.

Lett must be installed in perpendicular to the vibration flow. In certain cases it is necessary to assemble two lett to ensure good performances to fatigue life. Should this be the case, a suitable spring support must be placed to ensure stability (see sketch below). Fluid overflow inside lett can set off turbolences and noises that can damage and reduce its fatigue life. If so, it is highly recommended to switch to a bigger lett size.

The connection between lett and the pipe system is usually made by brazing. Lett unique special characteristics enable the fitter to perform such operations care-free from any overheating to the lett itself.

Lett test pressure must not exceed the nominal pressure x 1.5.

CORROSION PERFORMANCES

The materials of which lett is made fully suit the conveyed fluids, therefore no extra thickness is needed. Installer needs to pay special attention to protect lett from the environment corrosion factors

DISASSEMBLY

When you need to take down a lett – Cut the lett with a handsaw and not by flame cutting. make sure all the following steps are followed:

Drain all fluids from the piping system;

Clean the inside of the piping sytem;

Cut the lett with a handsaw and not by flame cutting.