• Production in compliance with world standards

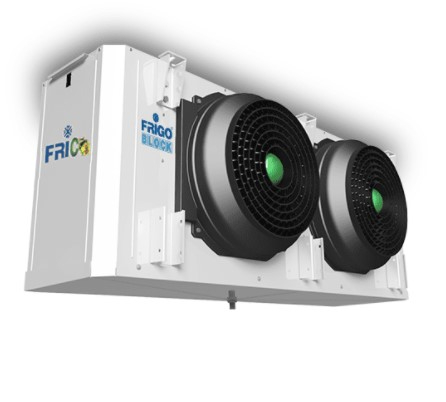

• Highly efficient cooling

• Low noise level outdoor unit compared to equivalents

• High-quality and reliable equipment

• The design ensures easy installation and mounting

• Wide product range

• Manufacturing in accordance with HACCP standards

• The unit's housing provides easy maintenance

• Evaporator design minimizes loss of product moisture

• Reduced the number of defrosts and increased defrost intervals for energy saving

• It is manufactured with a hermetic compressor as standard, optionally with a scroll compressor.

• It has an air-cooled condenser.

• It has a remote control panel with a user-friendly interface that enables easy setup of the desired parameters.

• It has robust housing according to the outdoor environment conditions.

• Evaporators can be produced with copper pipes as standard and with stainless steel pipes optionally.

• Evaporator fins can be produced with aluminum as standard, optionally with epoxy or blygold coated options.

• Evaporators can be produced as painted steel galvanized as standard and with stainless steel housing optionally.

• It’s delivered with positive pressure by pumping nitrogen to the inside and outside unit.

• The units are delivered as fully equipped to be ready for installation.

• The outdoor unit has an electrostatic painted steel galvanized housing.

Equipment in units

* It can differ according to unit model

• Phase protection relay (High/Low)

• Thermal / Magnetic circuit breaker

• Contactor(in three-phase models)

• Crankcase heater

• Copper tube aluminum fin condenser

• Liquid receiver

• Dryer

• Sight glass

• Liquid flow control solenoid

• Service / Maintenance valve (on the liquid line)

• Pressure switch (Low/ High)

• Gas charge valve

• Sound insulation

• Fan speed controller