- ADELINOX is one of Turkey's leading manufacturers of chimney and flue systems for exhaust gases and ventilation systems covering all kinds of domestic, commercial and industrial applications. ADELINOX product range includes 55 CE certified chimney systems covering all commercial and domestic applications. This wide range is complemented by self-supporting (free-standing) industrial steel chimneys up to 3 meters in diameter.

- ADEL INOX offers its customers a wide range of high quality products, technical support for special projects, chimney sizing services and a modern and dynamic company structure that can meet the wide variety of chimney requirements needed in the market.

- INNOVATION, DESIGN, SUSTAINABILITY

- As ADELINOX, we build our business understanding on these three main structures.

- We offer more effective and more efficient products to your benefit by redesigning our products according to current conditions and your needs and producing original products. While executing all these processes, while ensuring the continuity of production and product diversity, we are working to leave a more livable world to future generations with our goal of producing sustainable chimney solutions for a livable world from yesterday to today and tomorrow.

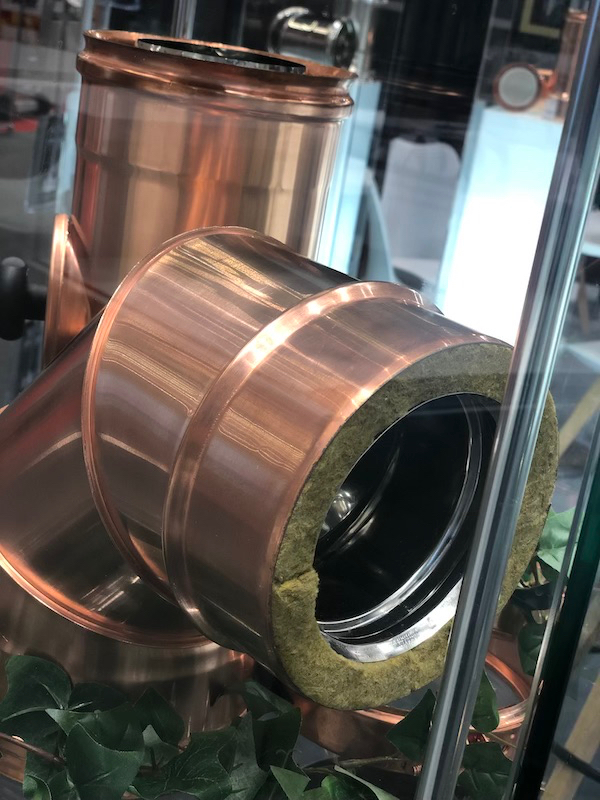

Chimney System

HS Code : 730799

Certificates :

Product Details

Technicial Specifications

Other products

About the Company

Contact

Usage areas

Heating and hot water boilers

Atmospheric, blown burner or condensing boiler systems

Solid, liquid and gas fired boiler systems

Steam and hot oil boilers

Wood stoves

Fireplaces

Pellet stoves

In-shaft flue systems

Cascade chimney systems

Chimney renovation operations

Industrial or domestic kitchen hoods

Ventilation systems

Waste gas systems of process devices

Outdoor chimney systems

Industrial plants, rolling mills, melting pots

Process and hood systems through which high temperature flue gas passes

Ram machines, textile industry

Paint and drying ovens

Features

Production with TIG and LASER welding technology

0.4mm – 2.00mm inner wall sheet thickness

Outer wall sheet thickness between 0.4mm- 0.8mm

25mm or 50mm insulation thickness

Standard production in diameters between Ø80mm – Ø1200mm

V2 corrosion resistance

Suitable for N1-P1-H1 systems

Resistance to soot fire

50mm special sealed structure

Advantages

Use in accordance with standards in different fuel types (solid, liquid, natural gas)

Quick and easy assembly

100% sealing with special structure

High efficiency is ensured thanks to low thermal permeability

Use in accordance with standards in different pressure classes N1 – P1- H1

Use in accordance with standards in different operating types D and W

Resistance to soot fire

Long life thanks to V2 corrosion resistance

Produces economical and aesthetic solutions thanks to different outer wall options