Product Details

Technicial Specifications

Other products

About the Company

Contact

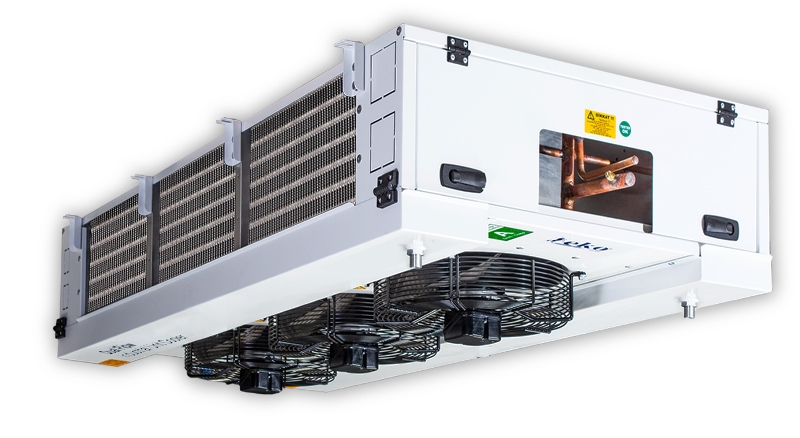

• All models are designed and produced the original designs.

• High-quality galvanize coated with powder polyester electrostatically, that provides

excellent corrosion protection.

• Used as the standard color RAL 7035.

• Stainless steel cassette is optional.

• Proper for food processing applications.

• Hinged folding drain tray is standard for all models. This applications provides easy

cleaning and maintenance.

• Side panels are removable as standard for easy maintenance.

• Casing has attractive view in addition to its rigidity.

• Electrical junction box and aluminium drainage discharge.

CASING

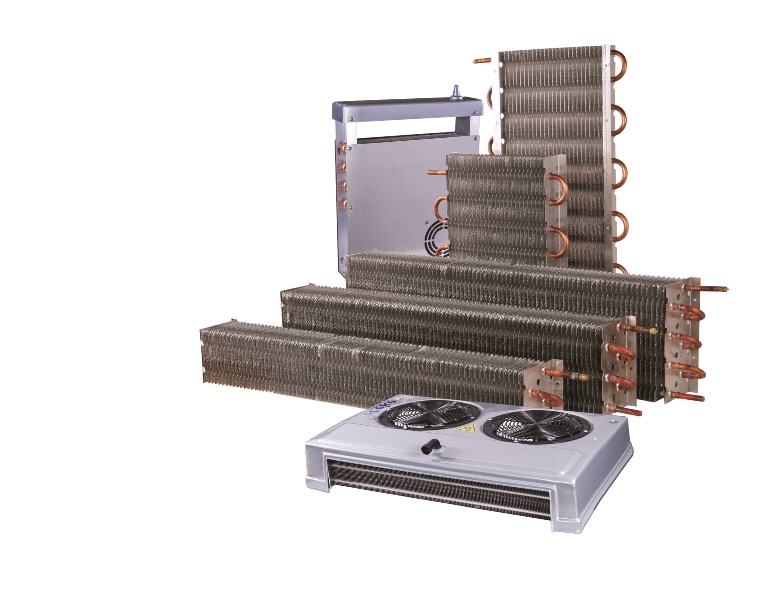

• High performance Unit Coolers are produced 5/8 copper tubes and from aluminium

fins which increase the heat transfer coefficient.

• Straight tube alignment that reduce defrost duration and defrost energy consumption.

• Refrigerant distributor.

• High efficient corrugated aluminium fins.

• Coil circuits are designed for high capacities and according to refrigerant.

• Test pressure: 30 bar. Products are delivered under azote positive pressure.

• Inlet and outlet connections are copper.

HEAT EXCHANGER

• Unit coolers deliver as standard without heater but heater are provided

upon customer request.

• R1 room temperature between 0 °C and 5 °C For light electrical

defrosting (defrost heater are applied on heat exchanger coil).

• R2 Room temperature below 0 °C. For normal electrical defrosting.

ELECTRIC DEFROST

• Unit coolers deliver as standard without fan but fans are provided upon

customer request.

• Fan diameter are changed between Ø300, Ø350, Ø400, Ø450, Ø500 mm.

(defrost heater are applied on both heat exchanger coil and drain tray)