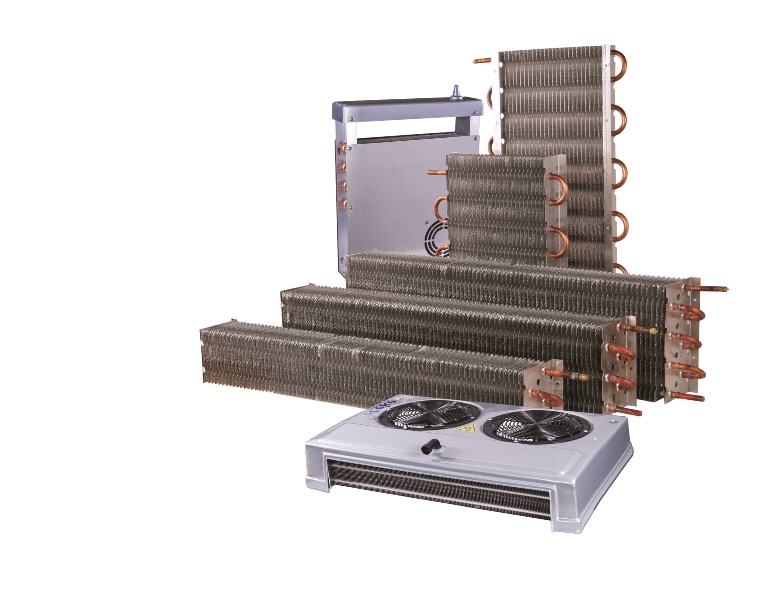

Product Details

Technicial Specifications

Other products

About the Company

Contact

All models are designed and produced the original designs.

• High - quality galvanize coated with powder polyester electrostatically, that provides

excellent corrosion protection.

• Used as the standard color RAL 9016.

• Stainless steel cassette is optional.

• Proper for food processing applications.

• With hinged side cover and double drain pan, it is the same in all models are designed for

practical maintenance and cleaning operations.

• There are output compartments in different directions for collector and electrical outlet.

• Side covers are easily removed and installed during assembly and maintenance operations.

• Casing has attractive view in addition to its rigidity.

• Intermediate drain pan prevents air by-pass.

• On junction box and drainage discharge aluminium.

CASING

• High performance unit coolers are produced 40x35 mm cross geometry with 1/2

copper tubes and high efficient fins.

• Refrigerant distributor.

• High efficient corrugated aluminium fins.

• Coil circuits are designed for high capacities and according to refrigerant.

• The system tested at 30 bar and delivered under positive pressure with azote.

• Inlet and outlet connections are copper.

HEAT EXCHANGER

• Unit coolers deliver as standard without heater but heater are provided

upon customer request.

• R1 room temperature between 0 °C and 5 °C for light electrical defrosting

(defrost heater are applied on heat exchanger coil).

• R2 room temperature below 0 °C for normal electrical defrosting

(defrost heater are applied on both heat exchanger coil drain tray).

ELECTRIC DEFROST

• Unit coolers deliver as standard without fan but fans are provided

upon customer request.