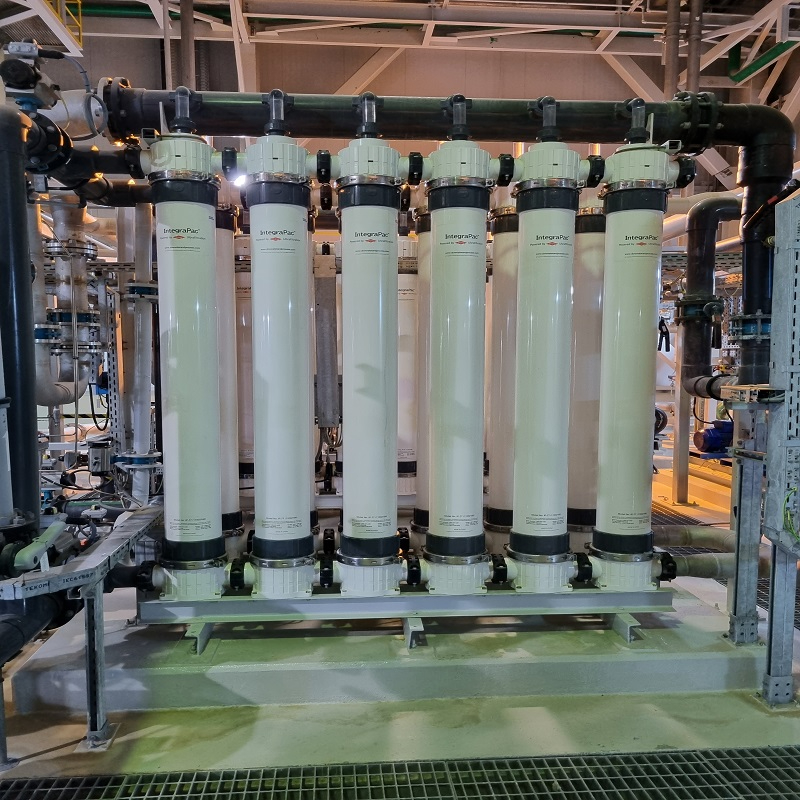

Product Details

Technicial Specifications

Other products

About the Company

Contact

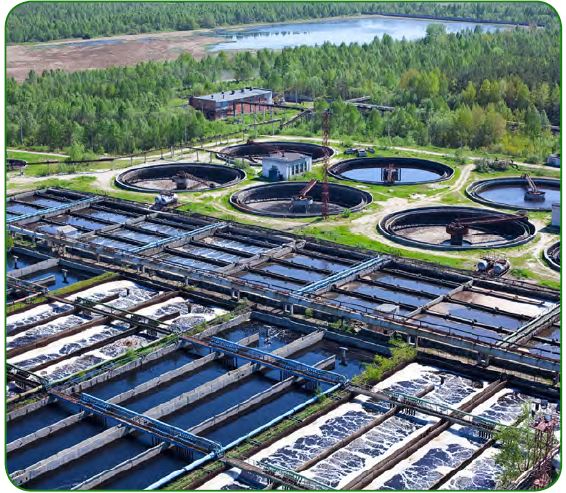

The high pressure water supplied in the feeding part of a semi-permeable membrane starts to move through the membrane winding. The gasket on the membrane, which creates a pressure difference on both sides of the membrane, forces the water moving in the membrane winding to pass through the membrane walls, separating most of the ions and other elements it contains. Due to the high pressure in the membrane feed, water molecules, and the special structure of the membrane that allows very small ions to pass through, start moving towards the low pressure environment and are largely separated from the pollutants. On average, the metal powder separation ability of a membrane is 97-99% and the calcium carbonate (hardness) separation ability is around 95%.

There is a continuous water flow in the membrane windings in order to remove the metal salts and other elements that the membrane has separated from the water (washing-flushing) and this water is discharged out. This water discharged from the device is called “waste or drain”.