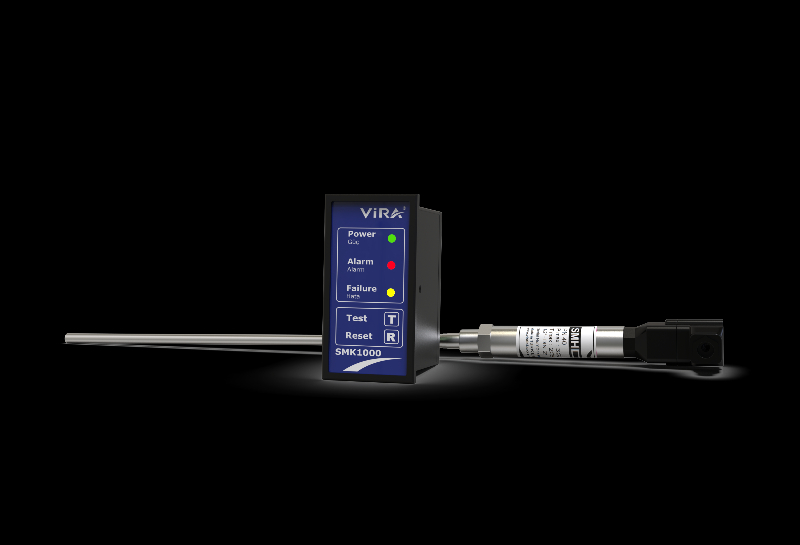

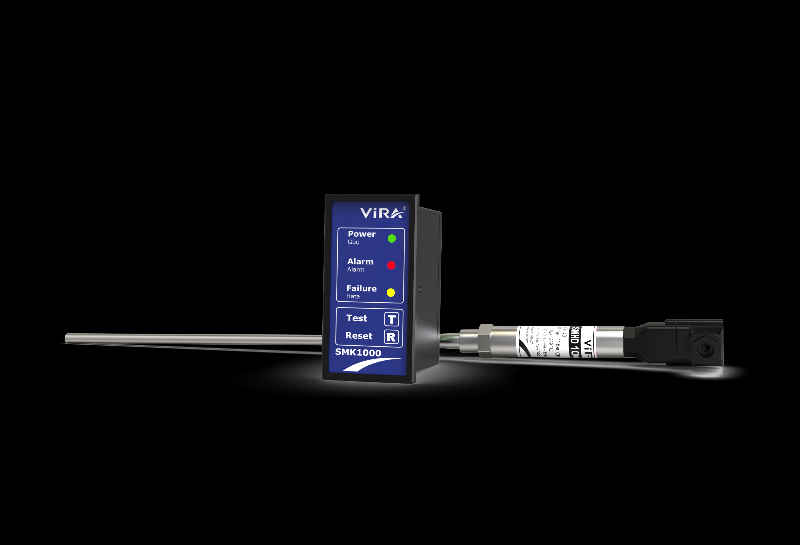

- The level controller SK 2400 is used in conjunction with level electrode SD 2400. to limit the water level in steam boilers and (pressurised) hot-water plants.

- Water level limiters switch off the heating (burner) when the water level falls below the set minimum level (low water).

Product Details

Technicial Specifications

Other products

About the Company

Contact

An On - Off signal for level control is the most common method of level controlling which is simply to start the feedpump at the low level and let it run until the high water level is reached within the boiler drum.

The SK 2400 Level Controller operates on conductivity principle for controlling the level in conductive liquids. The Level Controller with Probes are suitable for use with different qualities of liquids such as water, condensate and boiler water. On-Off Level Control Systems can be used in water with an electrical conductivity as low as 10 μS/cm at 25 ˚C.

On-Off Level Control systems are usually used up to 5000 kg/h steam flow rate. For higher flow rates Modulating Control System is recommended. Because, when the pump is on, the high flow rate of cold feedwater, reduces the boiler pressure and this may causes the followings;

- Burner Damages

- Quick Temperature Changes of the Boiler

- Efficiency Reduction

There is one fuction for each electrode. Each electrode can be cut to the required length to use on installation. Four different functions could be provided by Level Probe SD 2400:

- Pump On -Valve Open

- Pump Off -Valve Close

- 1st Alarm (Low or High)

- 2nd Alarm (Low or High)

By alarm relays, it is also possible to stop burner.