Product Details

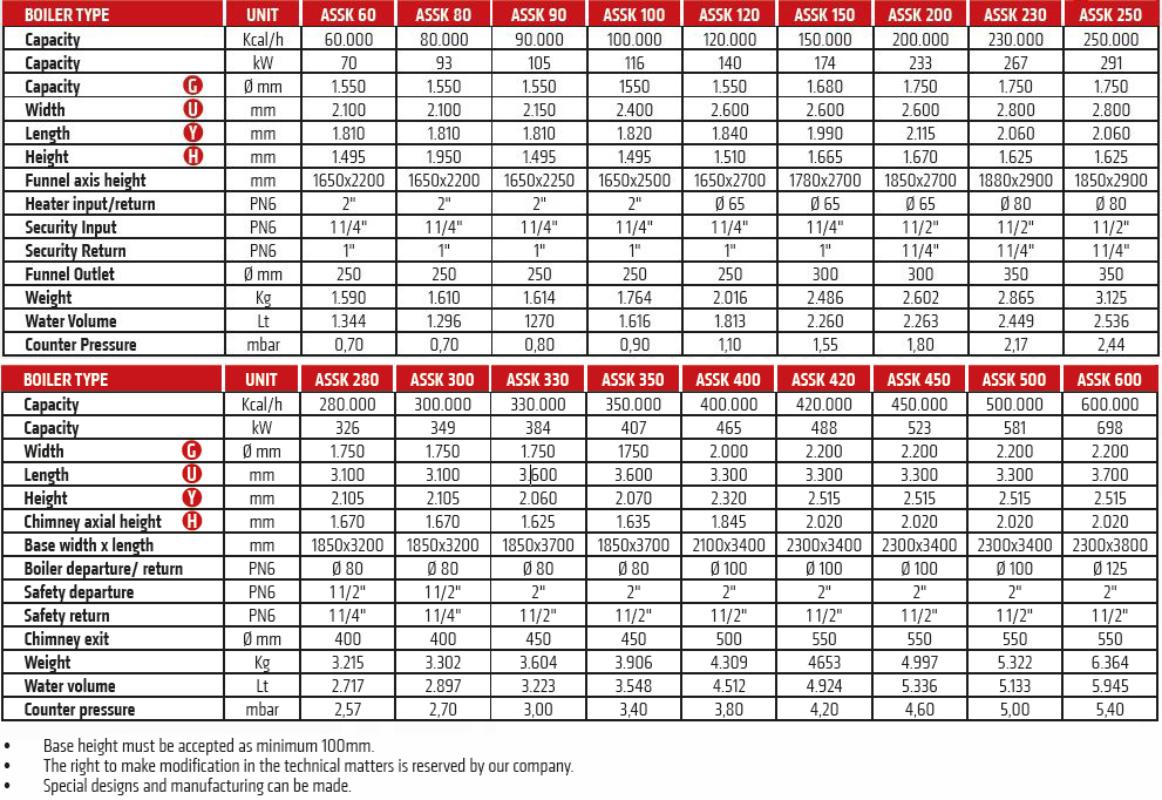

Technicial Specifications

Other products

About the Company

Contact

They work very quietly and efficiently owing to high design and construction technology.

ASSK type heating boilers have flare and smoke pipes and the boiler pipes are assembled to the mirrors by welding.

Type heating boilers have a three-transitive structure and the boiler lifetimes are longer than those of the counter-pressure and other types of boilers.

Have design and construction appropriate for burning with high efficiency of low-calorie lignite quarried in this country and solid fuels having high energy with their developed special burning chamber and grid design.

Their cylindrical scotch type structure and special design enable the fluid within the heating boiler homogenously and energy within the fuel is enabled to be transferred to the fluid with high efficiency.

Acts of the boiler under pressure are secured with their symmetrical cylindrical construction and pressure resistance of the boiler is improved relatively.

Thermic tensions, which occur during welding with the boiler plates that are cut in special angles, are distributed to the entire boiler surface homogenously and the boiler lifetime is extended.

Burning of economical solid fuels such as coal, wood, coking coal, hard coal and lignite coal is enabled with ALFA guarantee without compromising comfort and efficiency.

Their compact structure enabled with their small dimensions and low weight ease transportation and placement matters which are very important in high capacities.

Thermal efficiency values of ASSK type heating boilers are 86% and higher.

High-efficiency burning is achieved in conformity with automatic burning units and mechanical dust coal burning (AST stoker) systems.

They are commanded with low water volume and react to demands rapidly and they exceed the condensation limit depending on the fuel that is valid for all boilers in a short time and step in rapidly.

Heat insulation of the boilers is varied good. The entire boiler is coated with insulation material.

They are enabled to bum natural gas with a cap revision when desired.

AKP-S model control panel is used from capacity ASSK 90 to capacity ASSK 800. AKP-F model control panel is used with double contact limit thermostat from capacity ASSK 90 to capacity ASSK 800. ATP control panel is used with three-phase double contact limit thermostat from capacity ASSK 900. ADP- A model control panel is used in coal fuel heating boilers with a stoker.