Product Details

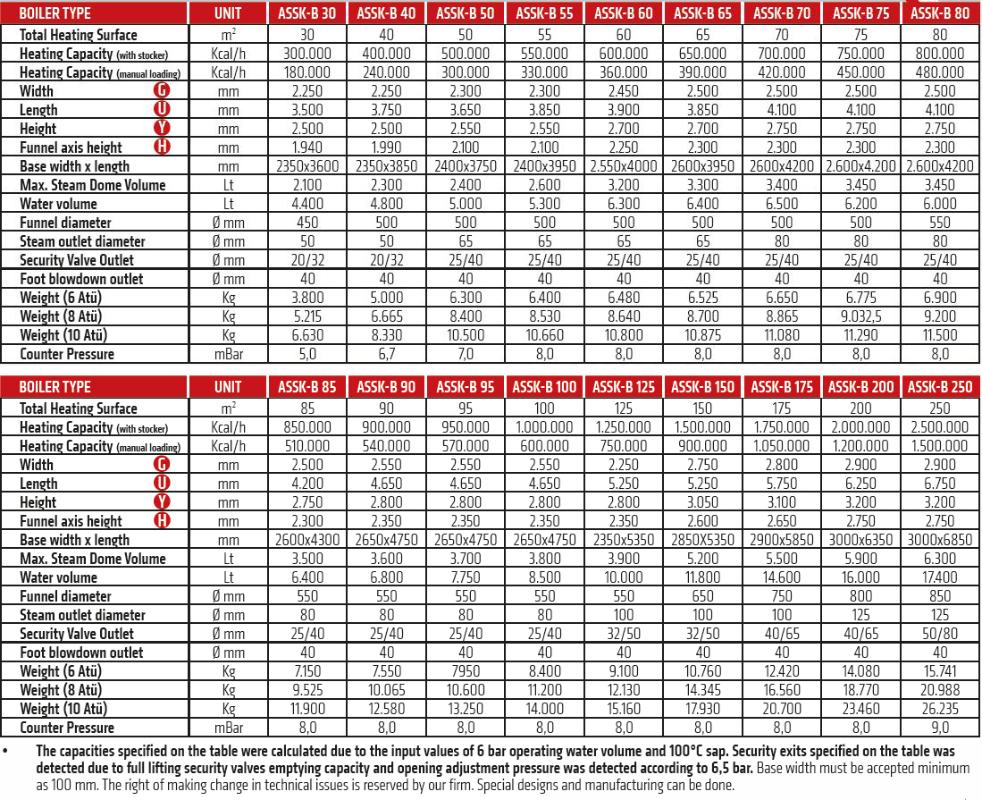

Technicial Specifications

Other products

About the Company

Contact

It complies with TS EN 12953, TS 377 standards.

It bums solid fuel with high efficacy.

Stoker crucible or grills within combustion chamber are removed easily and they are made suitable for burning liquid and gas fuel in a short time.

It is manufactured with computer-aided design and manufacturing technology in accordance with CE quality standards, TRD pressure vessels directive, EN, TSE standards.

Thanks to large water and steam, it easily meets the necessary steam need in intensive and persistent working conditions and sudden steam traction.

With the advantage of a high heating surface, it provides acquiring drier steam with higher energy.

It is three transitional and it allows maximum utilization from the fuel with tube bundle design between the transitions.

With low counter pressure values, it provides better burning and less energy consumption.

It operates safer with the pipes welded to the mirrors and it is more durable than the equivalents.

With optimum isolation, it ensures maximum efficacy and maximum performance.

Optimum combustion chamber dimensions ensure high heat transfer, radiation, more efficient usage of heat transfer surfaces, and the occurrence of full burning in the combustion chamber.

It provides high efficient full burning without economizers; it provides an environmentally friendly burning graph and reduces fuel consumption.

In order to meet customer expectations, it increases the production capacity range appropriate for need and the manufacturing is conducted.