Product Details

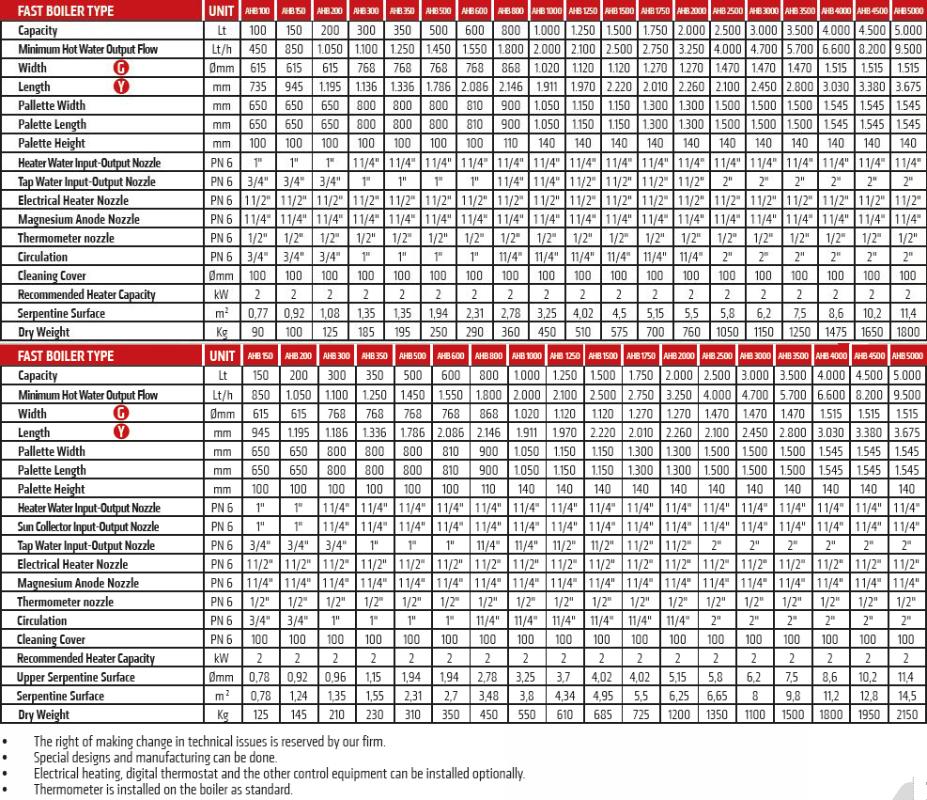

Technicial Specifications

Other products

About the Company

Contact

It has a cleaning cover manufactured in a vertical system within the scope of TS 736, TS EN 12897.

An electric heater can be installed when desired.

lts construction was conducted at 10 bar and in accordance with operating pressure.

Serpentine pipes were manufactured in accordance with EN 10217-2 standards.

It provides hygienic and plenty of hat water. They are also named Thermo Boiler.

It can be used as natural circulation or with a circulation pump.

The internal body of the boiler can be manufactured as hat galvanized dipping, enamel and epoxy painted. D it produces hat water at high capacities in narrow volumes.

Fast boiler is designed in a vertical position and the installation is performed as vertical.

It is ergonomic.

Hot water in the fıxtures can be adjusted at the desired ratio since the pressure in the usage area is as much as the pressure of tap water.

It is convenient for use in different climate conditions.

It can easily be located in high buildings and partitions.

It provides high performance in low-temperature differences within the system.

It has the feature of using magnesium anode.

It is convenient far operate in parallel with the solar energy systems and heater boilers.

It is convenient for European standards with resistance and efficiency values.

The water heat of the boilers can be continuously viewed on a digital screen (optional).

When pressed on the button on the lower right corner of the digital screen, it shows the level of magnesium anode probe as % and automatically returns to the heating screen (Optional).

There is a thermometer on fast boilers. Temperature and pressure in the boiler can be observed from the thermometer.

In fast boilers, armored electric cable spanned from upper cover to lower cleaning cover in isolation cover. This cable allows heating fast boilers with electric energy by making the electrical heating supplement and thermostat supplement on the upper cover.

In AHB fast boilers, polyurethane isolation application is used from AHB 100 capacity to AHB 600 capacity. Foam insulation and leatherette outer sheath application including from AHB 800 capacity to including AHB 3000 capacity and galvanized sheet application over glass wool from including AHB 3500 capacity to including AHB 5000 capacity is conducted.

Security valve must be installed on cold water feeding circuit as much as 10% of operating circuit.