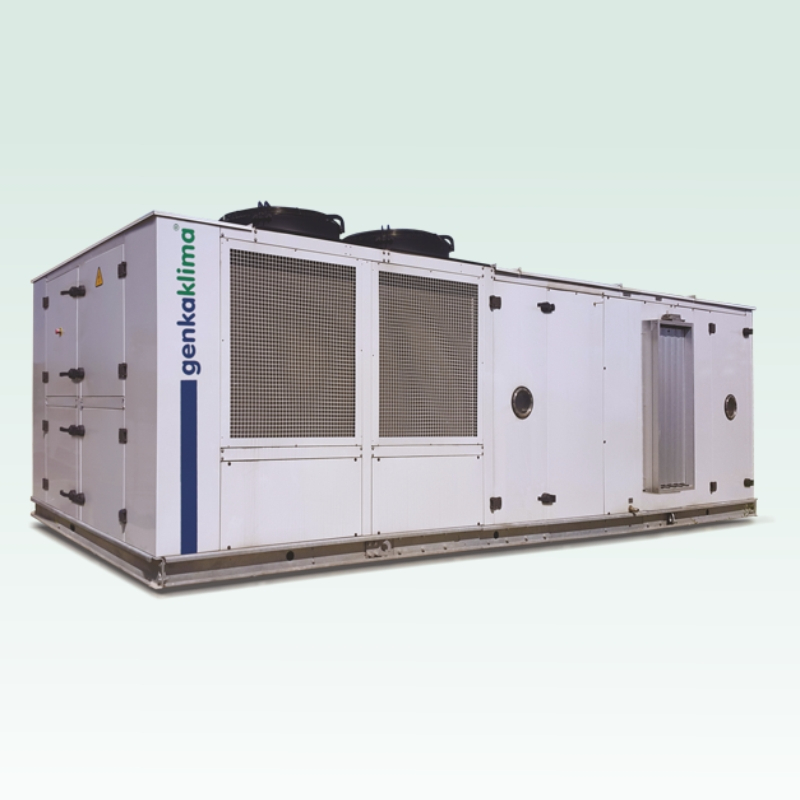

CENTRIFUGAL FAN COOLING TOWERS

GENKA GEN-CT series water cooling towers, used with industrial process cooling applications and water cooling facilities, are manufactured in 16 different types between the capacities 85.200kcal/h and 1.704.000 kcal/h. They provide water cooling by counter flow of water and air.Due to the use of double inlet low RPM centrifugal fans in GEN-CT cooling towers, the sound and vibration level is minimized to the lowest level available. The GEN-CT cooling towers are produced as open type cooling towers which are suitable for use in direct process water line or in an heat exchanger system.

GENKA GEN-CT cooling towers are differentiated from its competitors in two main features. One of the main feature is the high tech equipment that GENKA uses in its cooling towers providing the ultimate efficiency and capacity performance levels. The second feature is the advanced design in construction and surface treatment of the structural materials. GENKA GEN-CT cooling towers have longer duration of operation lifetime compared to the competing products which enables GENKA’s customers to have the return of their initial investment due to this feature and minimized service/maintenance requirement of the units.

GENKA GEN-CT centrifugal fan cooling towers’ structural body is standardly manufactured from surface treated applied steel. However on customer demand,stainless steel construction option is also available.

TOWER CASING AND RESERVOIR

As a standard application, tower casing is manufactured from sheet steel coated with electrostatically powder paint. If desired the casing can be constructed from galvanized sheet steel or stainless steel.The casing is connected to the reservoir which is constructed from hot dipped galvanized sheet steel with bolt and nuts. All connection surfaces are sealed with sealing gaskets and agents. GENKA uses sealing agents which are not effected from temperature changes and which are not loosing its sealing properties through time.

WATER DISTRIBUTION SYSTEM

Collector and distribution pipes in cooling tower applications are used in order to spray the water homogenously and pulverized to the filling materials. Specially designed spray nozzles are placed in certain distances on the distribution pipes. Collectors, distribution pipes and piping equipment are made from PVC material(including the water inlet collector flange connections.)

FILLING MATERIAL

PVC filing materials are used to enable maximum contact surface between the air and water. This type of filling material can be used with up to 50°C water temperature. For applications that are requiring above 50°C (max 85°C), polypropylenePP) injected filling materials called “curlings” may also be used as an alternative. For determining the correct filling application please kindly contact with GENKA .

DRIFT ELIMINATOR

GENKA GEN-CT Centrifugal fan cooling towers are equipped with drift eliminators in order to eliminate the water loss caused by the forced drafting of the water droplets carried by the air through outside the unit. The specially extruded eliminator profiles are located above the water distribution piping system and are causing minimum air side pressure drops. The collected water drops by the eliminator profiles are then directed to fall inside the unit.The eliminator profiles are standardly manufactured from PVC material which are mounted in highly robust cases. Eliminators can be made from polypropylene(PP),galvanized steel or stainless steel optionally if requested.

FAN-MOTOR COUPLE

The fans usd on cooling towers are of statically and dynamically balanced, belt driven, double inlet forward curved centrifugal fans. Forward curved centrifugal fans are working under minimum sound and vibration levels. Motors are of IP55 ingress protection class, F insulation class, 3 phased, 380V, 50Hz and body of casted aluminum. If requested by the customer, IP56, IP65 and IP 66 ingress protection class and Eex-Na(Ex-Proof) anti-spark motors can be used. The fans,motors and belts are protected from the surroundings with wire mesh and sheet casing as a standard application. Optionally an all fan-motor group can be delivered with a protection chamber equipped with a service door for maximum safety.