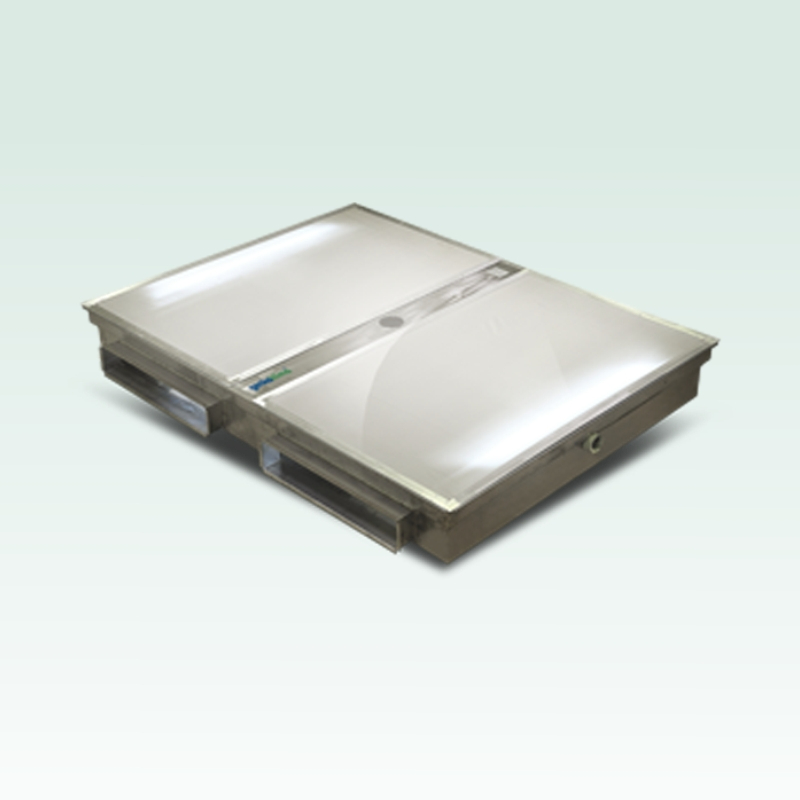

PACKAGED ROOF TOP AIR CONDITIONERS

GEN-RT series RoofTop Packaged Air Conditioners are designed to meet the special requirements of modern buildings. GEN-RT series uses R407C ,R134a and R410A refrigerants which are not harmful to ozone layer and are safe to use. Units are optionally used with heat pump, natural gas burner, hot water and electrical heater systems.

GENKA GEN-RT Rooftop packaged air conditioner’s axial condenser fans are controlled via frequency inverters. The fan rotational speed variably optimized in order to maintain the optimum pressure level on condensers continuosly. This feature is one of the most important difference that sets apart GEN-RT series from its competitors. All units manufactured in GENKA factories are individually tested in terms of mechanical,electrical,automation and refrigeration operation. This provides GEN-RT units to preserve its feature of “plug and operate” at site through all domestic and foreign projects.

GENKA GEN-RT Rooftop packaged air conditioners are standardly manufactured with single skin 25mm insulation. However upon request the units can be manufactured with aluminum profiles providing 25&45mm panel and can be manufactured with steel profiles providing 60mm panel insulation with double skin sheet metal. Unit duct connections are easily conducted via flanges on the front surface or the side surfaces which provides the elimination of roof curbs which are causing problems and additional costs at project site.

AIR COOLED CONDENSER

Galvanic corrosion free air cooled condensers are made up of from microchanneled aluminium tubes and aluminium fins. Galvanic corrosion which is seen in humid and salty ambients are not a problem in these condensers as a result of using the same material for the tubes and fins. Specially applied condenser coils and 920rpm low sound pressure type axial fans provide the necessary condensation. Fans are low rpm and high efficiency type which minimizes the dirt formation on the coil surface that causes excessive pressure and efficiency drops on condensers. Cleaning of this coil is also easier than the Cu-Al conventional coils. When compared to same capacity conventional Cu-Al condenser coils, microchannel type condenser coil provides 25% less air pressure drop, 65% less refrigerant side pressure drop resulting with a 45% efficiency increase. GENKA offers optionally the use of e-coated microchannel condensers on cases where the area of operation is with extreme humidity or atmosphere is highly corrosive such as industrial regions.

Units that are equipped with HeatPump option are standardly manufactured with conventional copper tube aluminum fin condenser coils. These coils can also be coated optionally with blygold/heresite type protective coatings.

INDEPENDENT REFRIGERATION CIRCUITS

According to required capacity, GEN-RT series roof top air conditioners are equipped between standardly 1 to 6 hermetic scroll compressors. The whole system can be with a single or multiple refrigerating circuits. Single compressor models can be manufactured with 2 compressors if requested. Hermetic Scroll type compressors are used as a standard application which can go up to maximum qty of 8 units.The direct expansion(DX) evaporating coil is aluminium fins- copper tubes type and it is feeded with expansion valve. All unit circuits have expansion valve, temperature-pressure sensors, valves, filter dryers, sight glasses etc. as a standard application.

R407C , R134A or R410a refrigerants are used in GEN-RT series. The refrigerants used are safe and not harmful to ozone layer. GEN-RT series rooftop units are equipped with VFD driven condenser fans to maintain the constant and optimized condensing pressure continuosly. Evaporator fans can also be equipped with VFD units to provide required air flow rate & pressure rates optionally.

PLC UNIT (PROGRAMMABLE LOGIC CONTROLLER)

All the operating and safety functions of the GEN-RT series roof top air conditioners are managed by a PLC unit.

The microprocessor allows accessing to the working parameters in two different ways;

Free access: Authorization level to access the temperature and humidity set points.

Access through customer password: Authorization level to access the alarm threshold and component state checking.

The unit controls are conducted via high tech PLC units. On the case that unit operates with additional optional equipment the or upon customer demand, optional and superior PLC’s to the standard ones can be used to comply with the unit input output requirements.

ELECTRICAL AND AUTOAMATION SYSTEM PANEL

The electrical board is fitted with a main cicuit breaker, phase-voltage control relay and has all the components necessary for the full functioning of unit without trouble. Also equipped with terminals for remote operation, indication of an existing alarm, and with additional terminals for starting and stopping the unit from a remote position. All units have their electrical & automatical control unit components in a single electrical panel and they are delivered with their own diagram as standard.The inverter unit that is used for axial fan control is applied inside the electrical panel.