Product Details

Technicial Specifications

Other products

About the Company

Contact

• Corrosion is the gradual destruction of materials, primarily metals, due to environmental effects, with metals being particularly susceptible due to their electrochemical nature. Metals with high stability (e.g., titanium) resist corrosion better than those with higher oxygen content (e.g., iron).

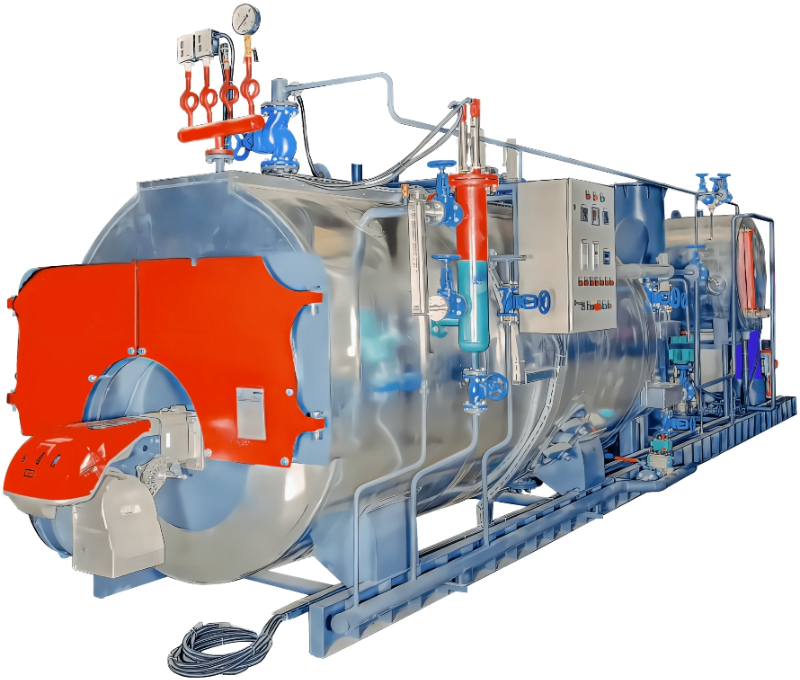

• Free oxygen (O2) and carbon dioxide (CO2) in steam boiler feed water can damage metal surfaces. To remove these gases, the water is atomized and heated, allowing CO2 to separate at 60°C and O2 at temperatures above 100°C.

• Deaerator’s Dome: Made from stainless or black sheet metal, this component includes a pulverization system and stainless steel trays, insulated with rock wool and either galvanized or aluminum sheeting.

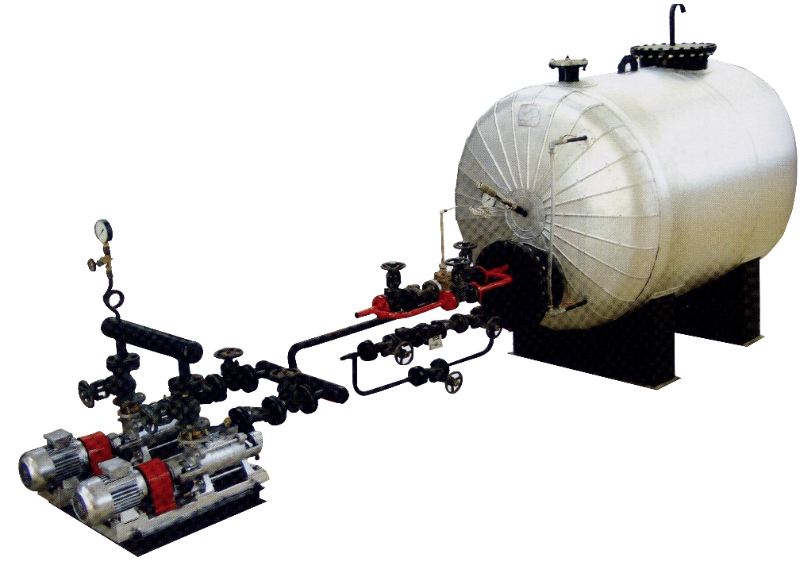

• Deaerator’s Tank: Constructed from St37 steel, this tank features a cylindrical shape with dished heads, insulated with rock wool and outer paint layers, and includes flanges for connections and a steam distribution collector.

• Exhaust Steam Condenser: This heat exchanger recovers heat from exhaust steam, preheating feed water while separating it from corrosive gases, with the condensate returned to the deaerator.

• Deaerator’s Fixtures: Includes various operational and safety components like pressure reducing valves, thermostatic valves, and level control systems tailored to the deaerator's type and capacity.

• Feed Pump: Centrifugal or cascade pumps, with pressures between 20 mSS and 25 mSS, are used to supply water to the deaerator, with selection based on the deaerator’s capacity and operating conditions.