Product Details

Technicial Specifications

Other products

About the Company

Contact

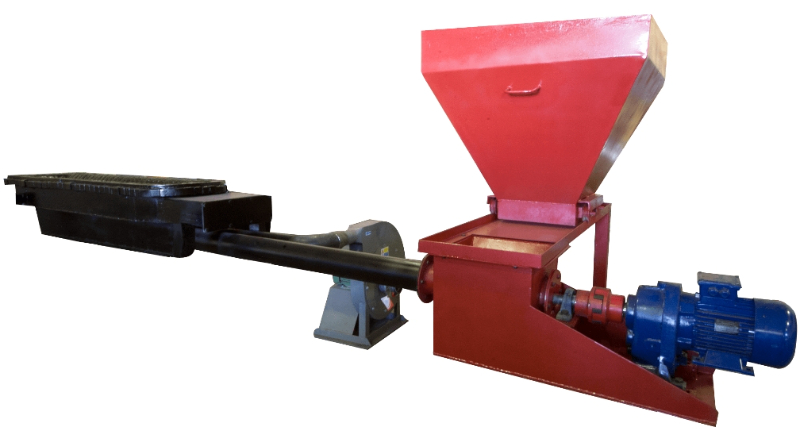

• Companies aim to use high-cost energy efficiently, often by recovering waste flue gas to produce hot water and air, as seen in RAM machines used in the textile industry.

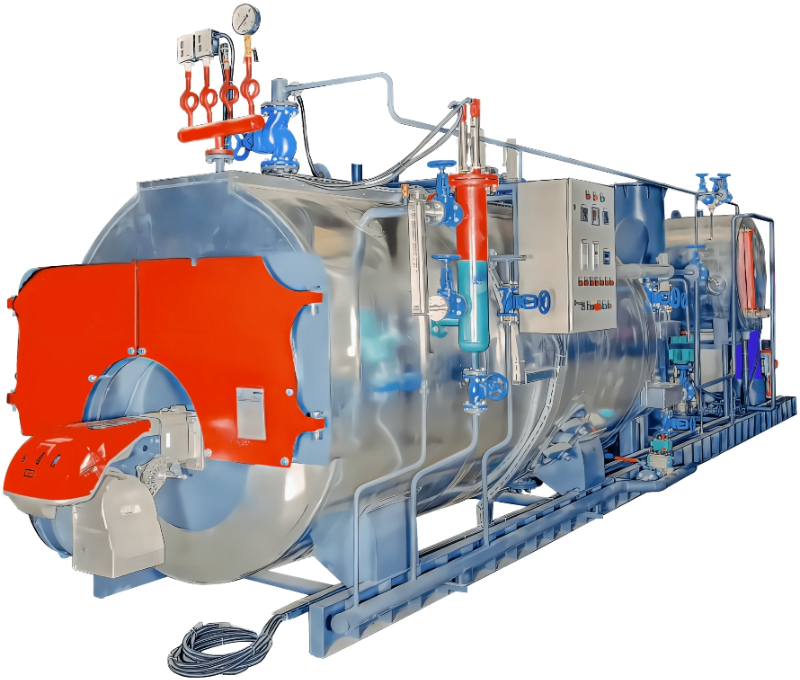

• High-efficiency boilers achieve efficiencies between 85% and 92%. Utilizing waste flue gas and hot water energy in sectors like textiles reduces production costs and benefits the economy.

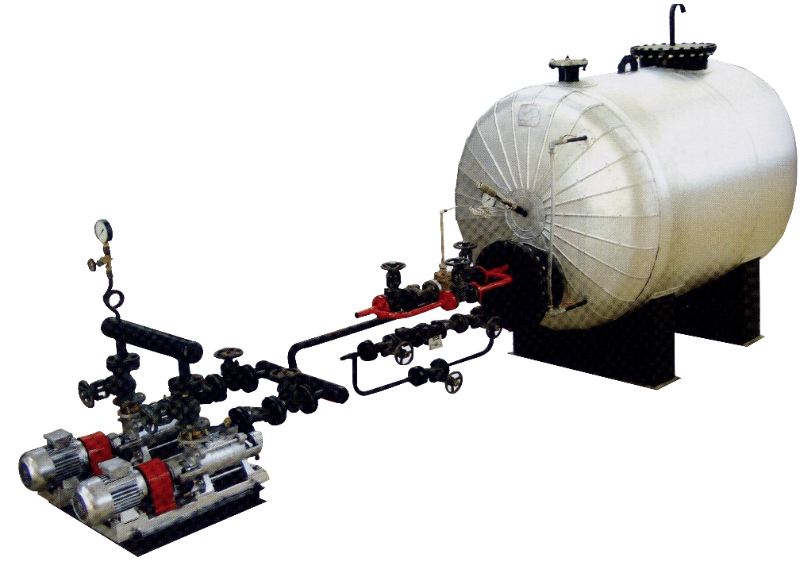

• Economizers, designed to save 3-8% of energy costs, offer substantial practical savings and improve installed capacity. They pay for themselves quickly and enhance heat transfer.

• In flue gas economizers, the choice of materials depends on gas properties and condensation temperatures. Acid-resistant materials are needed if condensation occurs, while carbon-steel can be used if condensation is avoided.

• Economizers lower flue gas temperatures, reducing excess air and associated efficiency losses. This minimizes the negative impact of excess air on overall efficiency.