- Shelter Ventilation Units

- When shelters are designed, the ambient air should be suitable for living conditions of living creatures benefiting from the shelter.

- In order to prevent radiation, biological and chemical dusts and particles to leak in the shelter, indoor positive pressure should be 50 Pa as compared to outdoors. The air in the shelter should not be heated, cooled and moisturized.

- There should be a protective ventilation system in the shelters along with a normal ventilation system.

Shelter Ventilation Unit

HS Code : 841581

Certificates :

Product Details

Technicial Specifications

Other products

About the Company

Contact

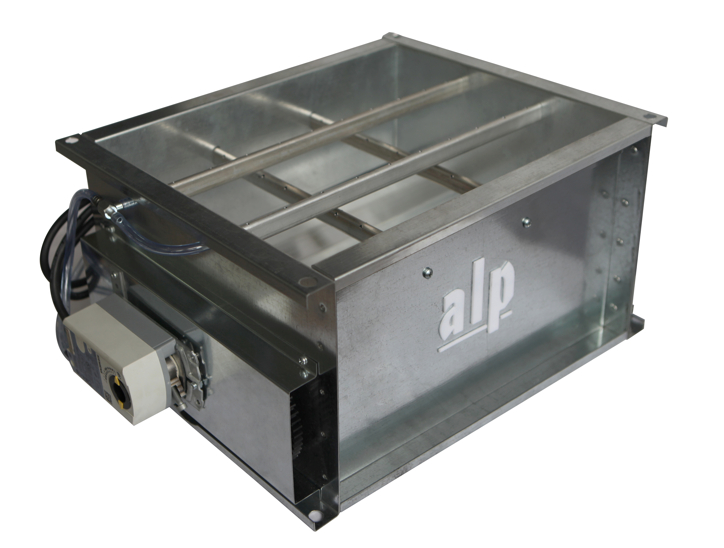

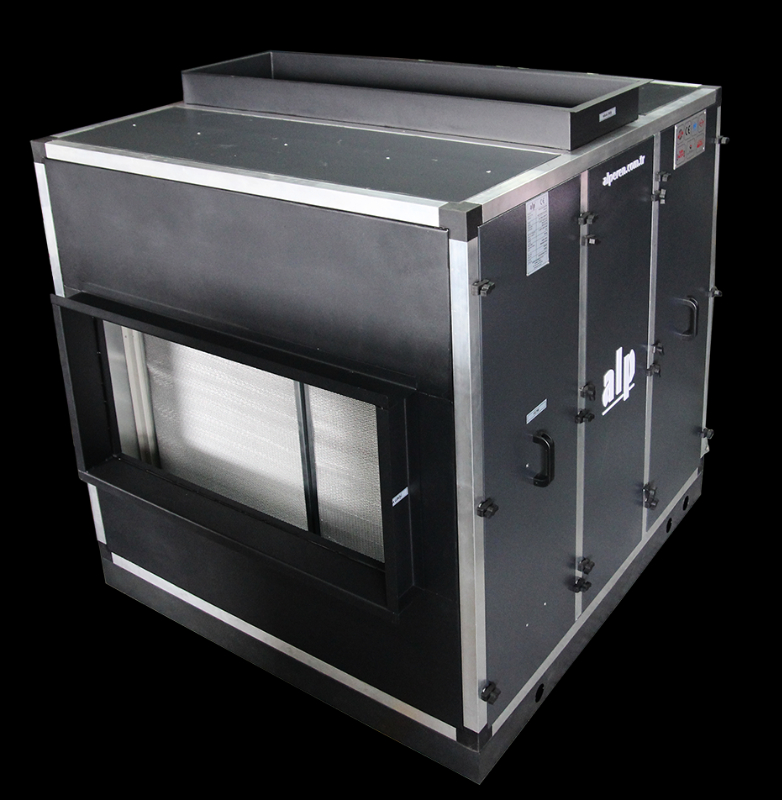

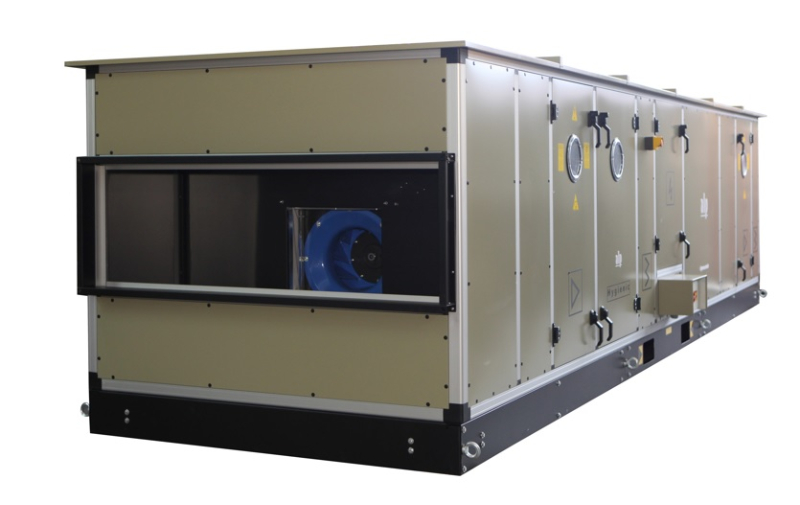

Structure of Alp Shelter Ventilation Units

The frame (carcass) of Alp Shelter Ventilation Units is made of natural anodized aluminum profile and corner elements. Cell panels are 42 mm-thick and the outer wall is made of galvanized sheet coated with electrostatic powder paint and inner wall is made of galvanized sheet. The space between the walls is filled with rock wool with density of 70 kg/m³. In order to be protected from harmful effects of X-Rays, inner walls of the cell can be covered with 1.20 mm-thick lead plates upon request.

The fans used in Alp Shelter Ventilation Units sare statically and dynamically balanced, silent, efficient, double suction, back sloping, thin bladed and radial.

Our electric motors are 380V-50Hz as standard.

All double wall panels are mounted on the aluminum carcass with screws. Service and inspection covers are void-free rigid hinged as standard and air-leakage

is not possible because of the compression. Airtight air conditioning unit locking system which doesn’t overhang in the cell is used. The covers are rigid and double-walled so they don’t rub the carcass frames.

Motor connection cables are enclosed in the junction box outside the cell.