- Hygienic Package Type Air Handling Units

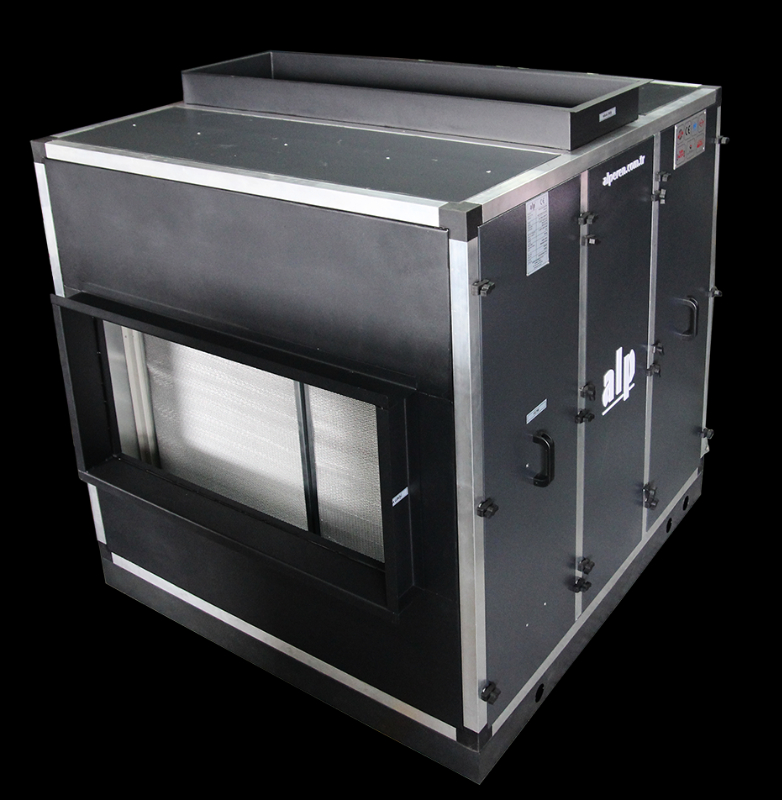

- Our hygienic package type air handling units are designed to meet all ventilation and air conditioning needs of all spaces that are desired to be sterile, with a single unit.

- Our hygienic package type air handling units are used in class 1 to class 1 air handling units, where you need high indoor air quality (IAQ) and a particle-free environment, especially in operating rooms, intensive care rooms, vaccine rooms, electronics industry, optical industry, pharmaceutical production facilities, food production facilities and chemical industry. They are produced considering the needs of the spaces classified according to the US Federal Standard 209E for 100,000, EN 150 14644-I for class 0 and class 7, and German VDI 2803-V for M1.5 and M6.5.

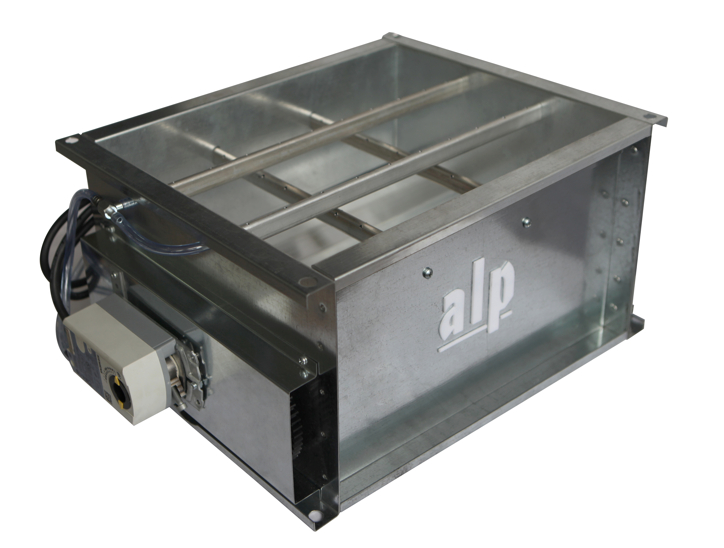

Hygenic Package Air Conditioner

HS Code : 841581

Certificates :

Product Details

Technicial Specifications

Other products

About the Company

Contact

Our hygienic package type air handling units comply with VDI 6022-1/3, DIN 1946-4 and EN 13053 standards. The inside of the power plant has been cleared of protrusions that may cause dust accumulation and flat surfaces have been created.

According to EN 1186, it is suitable for filter leakage class F9 and housing leakage class L2. Thanks to the silicone band that cuts the contact of the inner and outer sheet walls with each other, they do not form a thermal bridge and condensation does not occur on their surfaces.

Dust accumulation is prevented with antibacterial silicone seals applied to the joints. Our plants, which have a washable inner surface, have an extremely hygienic structure.

The air flow rates of our hygienic package type air handling units are manufactured as variable according to the desired values.

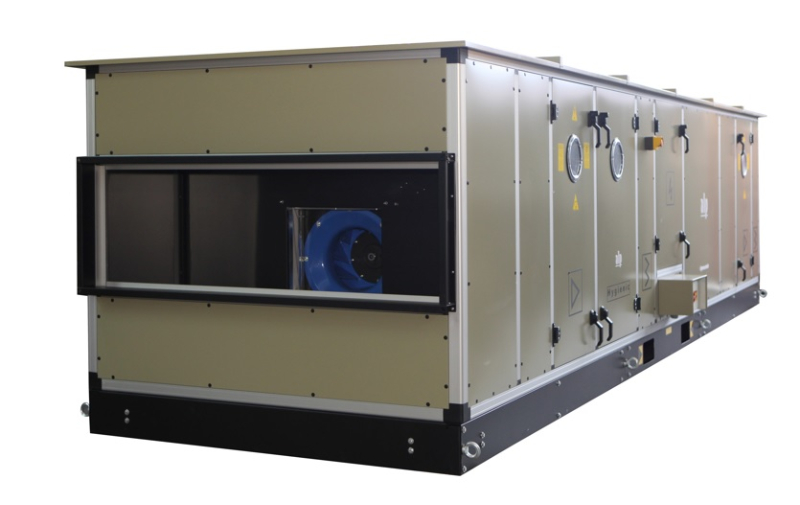

Placement of filters in our hygienic package type air handling units, G3 – G4 class and ultraviolet filters, which we can classify as coarse filters according to DIN 1946-4, are placed on the suction side of the fan and immediately after the air inlet. F7 and F9 class precision bag filters, compact filters and ozone filters are placed on the discharge side of the fan after a cell with a deflector.

H13 and H14 class hepa filters are placed in the interior of the place where they serve in clean room technology, just before the blowing terminal element. They are not placed inside the hygienic package type air handling unit. The air flow rates of Alp hygienic package type air handling units are produced as variable according to the desired values.

Alpine hygienic package air handling units, which have a modular structure, are produced in the flow range of 1,500 m3/h and 25,000 m3/h for all places that need to be sterile.