- Alp DX Air Handling Units

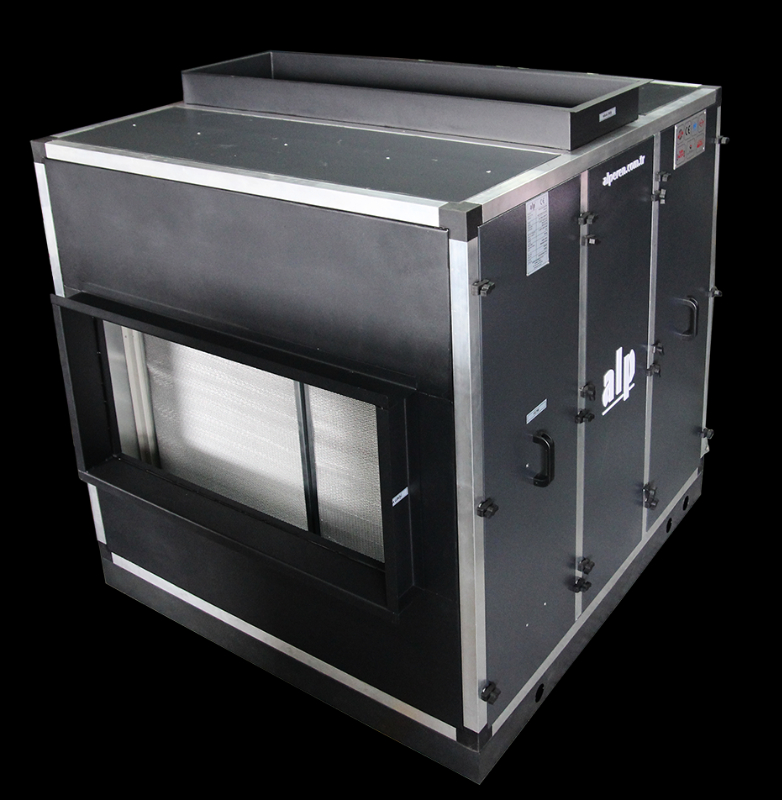

- Alp DX air handling units consist of combined module cells required based on your project.

- The frame (carcass) of module cells of our Alp DX air-conditioning plants are manufactured from natural anodized aluminum profile and corner elements. Cell panels are 42 mm-thick and the outer wall is made of galvanized sheet coated with electrostatic powder paint and inner wall is made of galvanized sheet.

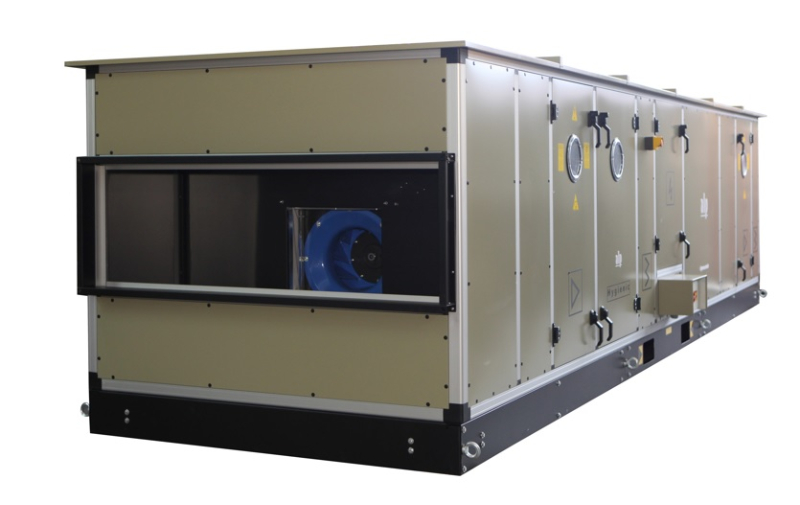

- Alp DX air-conditioning plants are an indispensable part of central ventilation and air-conditioning applications due to their high efficiency and energy saving, 70 kg/m3 dense rock wool filled panels, modern carcass structure, statically and dynamically balanced, silent and efficient plug fans. Our electric motors are 380V-50Hz as standard. EC motor high efficiency plug fans are also used upon request.

DX Air Handling Unit

HS Code : 841581

Certificates :

Product Details

Technicial Specifications

Other products

About the Company

Contact

All double wall panels are mounted on the aluminum frame with special torch tip M6 bolts. Service and inspection covers are rigid hinged and void-free as standard and airtight air conditioning unit locking system which doesn’t overhang in the cell is used. The covers are rigid and double-walled so they don’t rub the carcass frames. There are 180 mm-height chassis feet made of 2 mm-thick galvanized sheet under the cells. There are lifting lugs for craning and knife slots for carrying with forklift in the corners of chassis feet.

All grooves needed for automation such as grooves for differential pressure switch, NTC temperature sensor, freeze thermostat etc. are chamfered on Alp DX air handling units at production stage. Motor connection cables are enclosed in the junction box outside the cell. Automation equipment are collected on the panel of the device, fine-tuned and tested before delivery.

Cell joining elements are made of aluminum alloy material. Joining apparatus used to connect the cells with each other externally have a high-strength structure.

The interior lighting lamp and sight glass are placed in the aspirator, ventilator and filter cells of air-conditioning plants. These accessories enable inspection of the cells in an illuminated environment without deactivating the system.

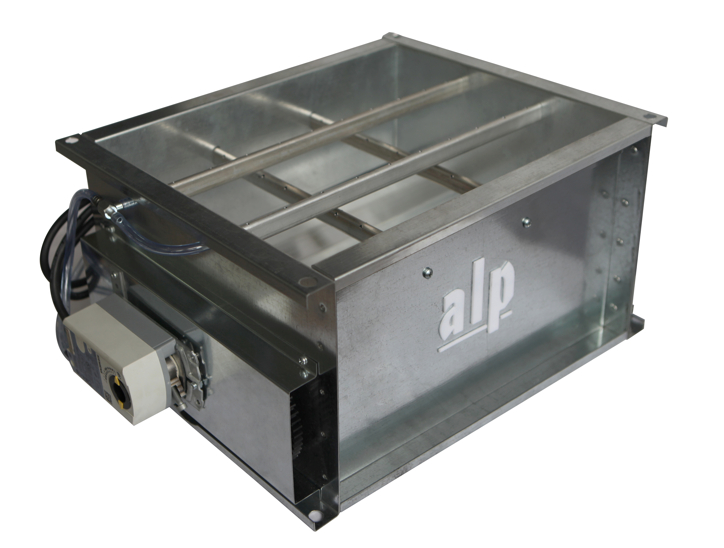

Usage Properties of DX Batteries:

DX batteries load the heat obtained from the air driven by a compressor passing through the evaporator to cooling fluid and cool the air or heat the air by performing just the opposite of this process.

An external VRF unit is connected to a direct expansion refrigerant battery adapted to air-conditioning plant. During this process the coolant is vaporized directly in the source of heat transfer, that is in AHU.

In heat transfer by conventional cooling groups like chillers or hot water boilers, the heat is first transferred to water and later on, heat is transferred in AHU by way of pipes and pumps.

An AHU with DX battery performs on-site air-conditioning with the operation of heat pump without the need of conventional cooling groups.

Alp DX air-conditioning plants use minimum energy and operate at high efficiency. They are airtight and minimize heat bridges. Special impact absorbers are used in Alp DX air-conditioning plants to prevent vibration caused by dynamic forces.

Alp DX air-conditioning plants are designed and selected on the basis of low operating costs and high efficiency.

Energy saving fans, efficient heat recovery exchangers and serpentines, and internal plant structure which optimally balances the air flow are used in our products to support these priorities.

Efficiency and energy saving are much better with our automation systems.