- HVAC Filter Selection

- What are HEPA and ULPA filters?

- HEPA stands for High Efficiency Particulate Arresting. It denotes high-efficiency particulate trapping. Hepa filters are the filters can that can eliminate particles down to 0.3 microns in proportions of 85% and above from the air. Filters that are more sensitive than Hepa filters are called ULPA filters which have a rate of 99.999%. HEPA and ULPA filters do not require maintenance and made up of special fibers, and have a structure similar to paper. These filters have to be replaced with the new ones within a specific period of time.

- Replacement of HEPA and ULPA filters are recommended between 6 to 12 months depending on the air pollution of the ambient where they are used, frequency of employment and pressure loss. Currently, HEPA and ULPA filters are employed in operating rooms, hospitals and clean room applications due to the filtering performance, reliability and maintenance-free structure thereof. HEPA and ULPA filters have models with MDF, plastic or metal frames.

Air Filter

HS Code : 842139

Certificates :

Product Details

Technicial Specifications

Other products

About the Company

Contact

What is bag filter?

Bag filters, made of synthetic fiber material, have high dust holding capacity and superior performance. Bag filters are manufactured with 500 mm and 600 mm depths are manufactured with special dimensions. Synthetic fiber bag filters are utilized in air-conditioning systems. In hygienic air conditioning systems they are assembled in the air handling unit with a view to keep the large particles and protect the HEPA filters. Synthetic fiber bag filters perform filtration in the “G3 (EU4) – G4 (EU4) – F5 (EU5) – F6 (EU6) – F7 (F7) – F8 (EU8 ) – F9 (EU9)” classes.

What is activated carbon filter?

Active carbon filters have the ability to capture and keep gas molecules. The surface of the active carbon filter consists of millions of tiny pores. Odor-emitting toxic gases are captured thanks to cited pores. Activated carbon filters should be replaced depending on pollution of the media air where they are used and frequency of use. For example activated carbon filters should be replaced every 3 to 6 months, in a smoking environment. Activated granular carbon filters are used as odor eliminator filters in places where heavy odors occur. When the filter gets dirty in activated granular carbon filters only granular carbons are replaced. There is no need to change the cells of the filters.

What is Cassette Filter?

Cassette panel filters are made of specially blended fiber raw materials with controllable and renewable and have an extremely durable structure. The protection cage around it is placed with an eye to protect the filtering feature from impacts. Cartridge panel filters are “G2 (EU2) – G3 (EU3) – G4 (EU4) – F5 (EU5) “class filters. Cartridge filters are produced as cellulose based and fiber glass based.

“Alp filters”-table1.jpg

Am% : Average dust capture ratio for the prefilters in the “G1 – G4” class.

Em% : Average yield for precision filters in the “F5 – F9” class.

% : Average yield for hepa and ulpa filters in the “H10 – U17” class.

MPPS : Most penetrating particle size of the filter.

Which filter should I use?

Filter selection table hereinabove will help you in this regard. Furthermore, our technical support professionals will be glad to help your esteemed side if you reach us through our e-mail address alperen@alperen.com.tr or telephone number +90 212 503 35 36 pbx

When should the filters be replaced?

The resistance that the filter shows against the airflow when it is clean is called initial resistance or pressure drop. The unit of pressure measurement incident to foregoing is called as Pa (Pascal) value. This value increases as the filters get dirty. The filters whose resistance value reaches the recommended final resistance must be replaced.

The last resistance values determined for prefilters and bag filters are recommended according to EN 779 European standards and you can examine these technical values on our website at www.alpfiltre.com.

What is the life of filters?

The answer to this question depends on the air pollution where the filters are installed. Factors such as elimination or addition of the air pollutants, and seasons have impact on the life of the filter.

Based on our experience we can say that the life of the cassette filters are 2 to 3 months while that of bag filters are 4 to 6 months and life of HEPA filters are 6 to 12 months.

Which filters are washable?

Prefilters that have polyurethane or metal internal structure are washable. Bag, HEPA and ULPA filters filter invisible particles by attracting and attaching them to the fibers of the filter on the basis of molecular attraction. These types of filters cannot be cleaned, repaired or replaced.

PREFILTERS

CBT • Fiberglass Paint Arrestors

Aim of Use : Used as dry type, dust arresting prefilter.

Features : Have high dust holding capacity.

Area of Use : Used in paint shops, paint booths, compressors and industrial air conditioning systems as rolls or by placing in panels.

Production Method: Produced in standard rolls of very thin glass fibers from finished paint stop filter material.

Efficiency Class : G2 (EU2) – G3 (EU3)

SER • Synthetic Fiber Rolls

Aim of Use : Used as low pressure loss, dust arresting prefilter.

Features : Have high dust holding capacity.

Area of Use : Used in air conditioning systems by placing in panels.

Production Method: Produced in standard rolls of 100% polyester fibers in nonwowen structure.

Efficiency Class : G2 (EU2) – G3 (EU3) – G4 (EU4) – F5 (EU5)

MTF 600 S • Waxed Ceiling Filter

Aim of Use : Used as low pressure loss, dust arresting filter

Features : High-density and supported by mesh network

Area of Use : Used in ceilings of paint booths

Production Method: Produced as waxed or no-wax synthetic fibers in rolls with all layers glued to each other by heat treatment.

Efficiency Class : F5 (EU5)

PYF • Polyurethane Washable Filter Materials

Aim of Use : Used as dust arresting prefilter.

Features : Washable filters.

Area of Use : Used in central air conditioning systems and fan coils as prefilter.

Production Method: Produced from porous polyurethane as standard plates or in desired sizes

Efficiency Class : G2 (EU2) – G3 (EU3)

ITM • Wet Paint Holders

Aim of Use : Used as paint arresting filter.

Features : The filter arrests liquid particles such as paint and etc. efficiently.

Area of Use : Used in ships, plastics, food, agriculture, metal and wood industry.

Production Method: Produced from moister resistant two-ply kraft paper pleated and glued together in standard size boxes

Panel Filters

FCF • Fan Coil Filters

Aim of Use : Used as dust arresting prefilter.

Features : Provides filtration in low efficiency and low pressure loss.

Area of Use : Used in fan coil units and air conditioners.

Production Method: Produced from synthetic filter material or washable polyurethane material in the desired sizes.

Efficiency Class : G2 (EU2) – G3 (EU3)

FCF / S : Synthetic fiber

FCF / P : Polyurethane (washable)

PMF • Panel Metal Filters

Aim of Use : Used as grease arresting washable prefilter.

Features : Has the property of grease arresting and long lifetime.

Area of Use : Used in kitchen hoods and ventilation systems.

Production Method: Produced from galvanized sheet metal or aluminum frame in the desired size by using a fine-mesh wire

Efficiency Class : G1 (EU1) – G2 (EU2)

PMF / A : Internal structure made of aluminum wire with galvanized steel frame

PMF / G : Internal structure made of galvanized wire mesh with galvanized steel frame

PKF • Panel Cassette Filter

Aim of Use : Used as dust arresting prefilter.

Features : Has the property of low pressure loss and high dust arresting capability.

Area of Use : Used in ventilation systems.

Production Method: The synthetic filter material is placed in metal or cardboard frame inthe desired size, supported by wire mesh Efficiency Class : G2 (EU2) – G3 (EU3) – G4 (EU4)

PKF / C with Cardboard Frame

PKF / M : with Metal Frame

STF • Synthetic Bag Filters

Aim of Use : Used as high-capacity dust arresting prefilter.

Features : Model with pocket showing high performance in difficult operating environments.

Area of Use : Used in ventilation systems.

Production Method: Produced from synthetic filter material placed in galvanized steel frame in the desired size

Efficiency Class : G3 (EU3) – G4 (EU4)

Bag & Compact Filters

HTF • Precision Bag Filters

Aim of Use : Used as second stage dust arresting filter after prefiltration.

Features : Filter pockets were sown as small sized pockets with an eye to achieve maximum efficiency from the entire surface area through employment of small synthetic fiber seperators.

Area of Use : Used in ventilation applications requiring high efficiency and precision filtration.

Production Method: Produced from sonic-welded, high-quality in the desired size, three-layer

synthetic filter material.

Efficiency Class : F5 (EU5) – F6 (EU6) – F7 (F7) – F8 (EU8) – F9 (EU9)

HTF / M : with Galvanized Frame

HTF / P : with Plastic Frame

KVF • Compact V Filters

Aim of Use : Used as second stage dust arresting filter after prefiltration.

Features : Large filter surface provides high air flow and low pressure loss. Can be used safely at high air flow thanks to light weight and compact design.

Area of Use : Used in places requiring precise filtration such as hospitals, pharmaceutical factories, clean rooms, industrial facilities and etc.

Production Method: Produced from high-quality filter paper in standard sizes and placed in plastic frame

after being folded in mini pleat design.

Efficiency Class : F6 (EU6) – F7 (F7) – F8 (EU8)

F9 (EU9) – H10 (EU10)

KPF • Compact Panel Filters

Aim of Use : Used as second stage dust arresting filter after prefiltration.

Features : Filters with single flange are easily used in applications

where mounting cell is narrow.

Area of Use : Used in places requiring precise filtration such as hospitals, pharmaceutical factories, clean rooms, industrial facilities and etc.

Production Method: Produced in standard sizes with plastic frame resistant to aluminum, paper or heat

and impact.

Efficiency Class : F6 (EU6) – F7 (F7) – F8 (EU8) – F9 (EU9)

KPF / A : with Aluminum Frame

ASF • Panel Filters with Aluminum Separator

Aim of Use : Used as second stage dust arresting filter after prefiltration.

Features : Used for applications where high airflow and high operating temperatures exist

Area of Use : Used in places requiring precise filtration such as hospitals, pharmaceutical factories, clean rooms, industrial facilities and etc.

Production Method: Produced from filter paper in standard sizes, separated from each other by aluminum separators flangeless or with a single flange or with double flanges.

Efficiency Class : F6 (EU6) – F7 (F7) – F8 (EU8) – F9 (EU9)

KPF / P : with Plastic Frame

KPF / K : with Cardboard Frame (flangeless)

Hepa and Ulpa Filters

PHF • Panel Hepa Filters

Aim of Use : Used as last stage high-efficiency particulate arresting filter.

Features : Offered with test results conducted according to EN 1822 with the productto the user.

Area of Use : Used in places requiring precise filtration such as hospitals, pharmaceutical factories, clean rooms, industrial facilities and etc.

Production Method: Produced from fiber glass paper after being folded through mini pleat technology and by placingin MDF or aluminum frame by closing the frame edges with polyurethane based glue

Efficiency Class : H10 (EU10) – H13 (EU13) – H14 (EU14) – U15 (EU15)

PHF / A : with Aluminum Frame PHF / M: with MDF Frame

HVF • High Flow Hepa Filters

Aim of Use : Used as last stage high-efficiency particulate arresting filter.

Features : Offered with test results conducted according to EN 1822 with the product to the user.

Area of Use : Used in high flow in environments that require hepa level filtration.Production Method: Produced from micro-glass fiber paper lined in V shape after being folded through mini pleat technology and by placing in galvanized frame by closing the frame edges with polyurethane based glue.

Efficiency Class : H10 (EU10) – H13 (EU13) – H14 (EU14) – U15 (EU15)

HDF • Hepa Terminal Hood Filters

Aim of Use : Used as last stage high-efficiency particulate arresting filter with hood.

Features : Allows complete sealing and easy usage. Offered with test results conductedaccording to EN 1822 with the product to the user.

Area of Use : Used in pharmaceutical, electronics, food and chemical industries other industries that require very high degree of fresh air. Production Method: Produced from hepa filter placed in sealed frame with hood that can be easily mounted between the T-shaped ceiling profiles. Efficiency Class : H13 (EU13) – H14 (EU14) – U15 (EU15)

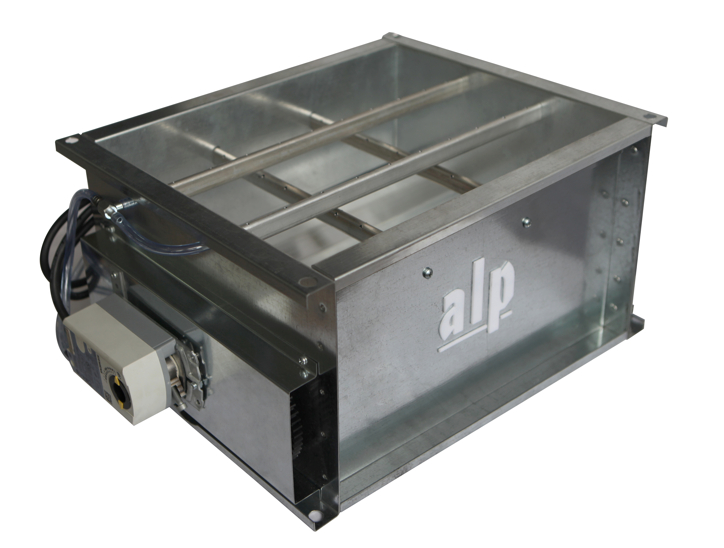

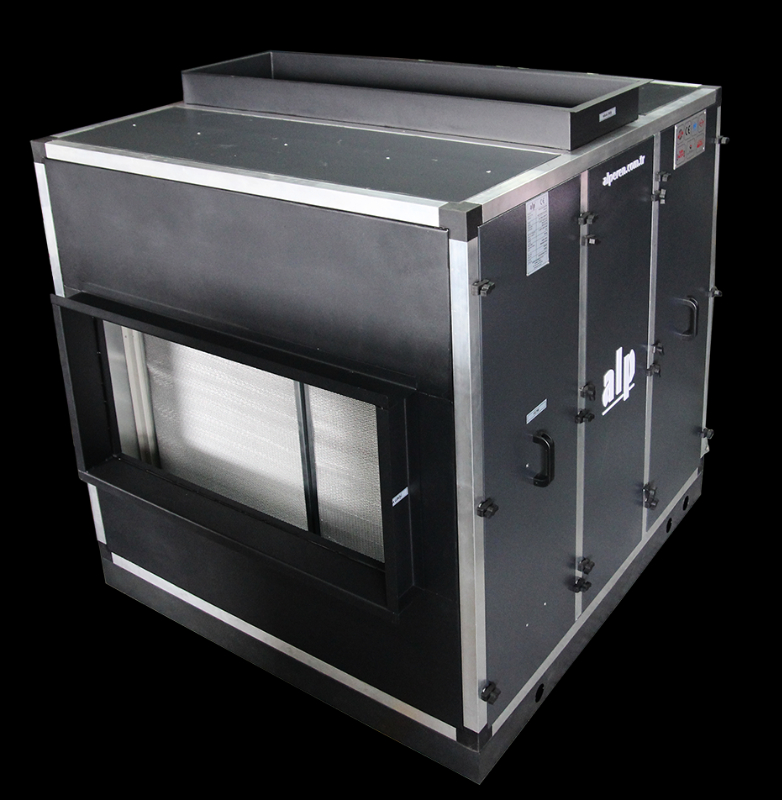

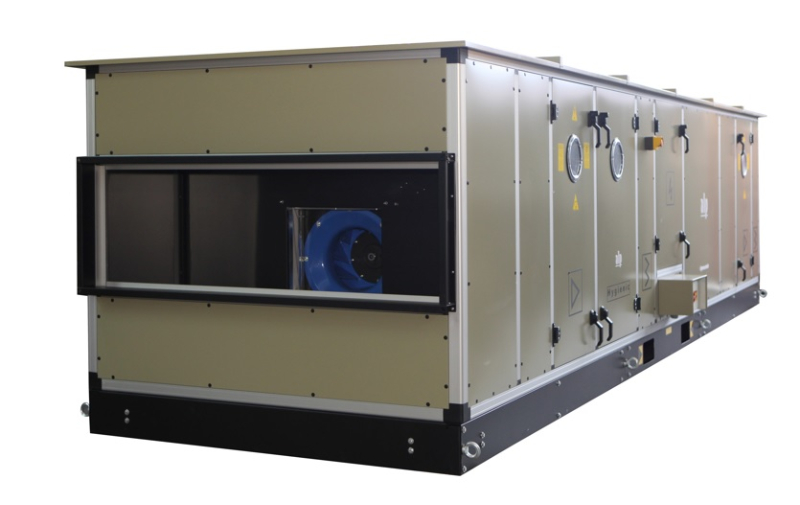

HEPABOX • Hepa Boxes

Aim of Use : Denotes the hygienic ventilation equipment used for the installation of hepa filters.

Features : Allows complete sealing and easy usage. Air intake is from the sides or from the top. Tested in accordance with DIN 1946/4 and offered to usage with 100% impermeability guarantee.

Area of Use : All projects where hepa filter applications to be utilized Production Method: Produced from stainless steel or powder coated steel sheet.

Active Carbon Filters

APF • Activated Carbon Panel Filters

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Impregnated with activated carbon powder. Provides odor retention with 30 to 35% efficiency

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well as alcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced from active carbon powder impregnated synthetic filter material placed inmoisture-resistant cardboard frame and supported with wire mesh folded in zig-zag form.

ADF • Activated Carbon Filling Filters

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Is easy to install thanks to its compact structure. Provides high odor retention with 80% – 90% efficiency.

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well asalcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced by filling the plastic panels that make up the filter frame with activated carbon granules.

AKF • Activated Carbon Compact Filters

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Provides high odor retention with 80% – 90% efficiency and ensures F7 class filtration efficiency thanks to the two-layer filter material and activated granular carbon particles thereof.

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well asalcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced by activated carbon granules placed between two synthetic filter layers.

KKF • Activated Carbon Cartridge Filter

Aim of Use : Used as the second and third stage odor arresting filter after pre-filtration.

Features : Provides high odor retention with 80% – 90% efficiency. Can be filled easily with clips placed on the covers

Area of Use : Used for arresting odors such as paint, varnish, solvents, thinner odors and hospitals odors as well as alcohol, tobacco and cosmetic odors in addition to organic odors such as food and rotten meal odors.

Production Method: Produced of galvanized metal in cylindrical shape in models with 4, 6, 8 and 16 cartridges with openable covers which facilitates the replacement of active carbon granules in it layers.

AGK • ACTIVATED GRANULAR CARBON

Aim of Use : Used as odor arresting filter material.

Features : Provides high odor retention with 80% – 90% efficiency.

Area of Use : Used in carbon filters and non-standard filter applications.

Production Method: Produced of mini carbon particles with 4 mm diameter and in various sizes.