- Concrete Temperature Control Systems

- Concrete Cooling Systems

- Temperature is one of the chief factors that affect the quality of concrete adversely. Temperature, at the same time, causes problems in mixing, placement and curing operations. The majority of these problems results in increasing in the rate of hydration and the rate of evaporation of the water in the fresh concrete mixture.

- Following incidents occur as the concrete temperature increases:

- The requirement for water increases,

- Consistency loss increases,

- Setting duration shows irregularities,

- Sweating rate and duration become unstable,

- Increased tendency to cracking in plastic and drying contraction develop,

- Increased risk of the formation of cold joint,

- The control of the air content becomes more difficult.

- Aesthetic appearance deteriorates.

Concrete Cooling System

HS Code : 841869

Certificates :

Product Details

Technicial Specifications

Other products

About the Company

Contact

Temperature, affects also the durability properties of the concrete adversely. As such, negative effects of the temperature on the concrete must be monitored and appropriate measures must be taken.

This issue was solved by mixing ice or cold water to the mixing water of the concrete until present. However, it has been observed that the method of mixing ice or cold water has become insufficient to obtain the desired quality of concrete in special concretes, especially on days when the air temperature is high.

The “spot cooling” method developed in recent years is based on cooling the concrete after placing or in other words after pouring the concrete into the mold, and in works carried out through this method high concrete quality in the desired norms has been reached.

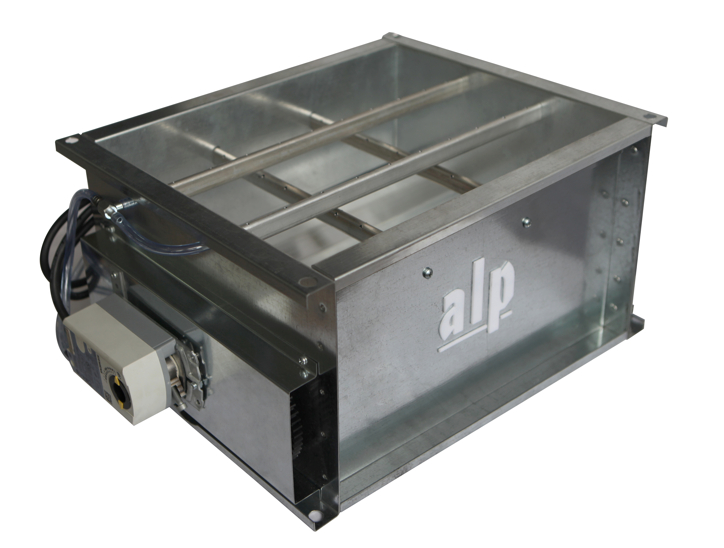

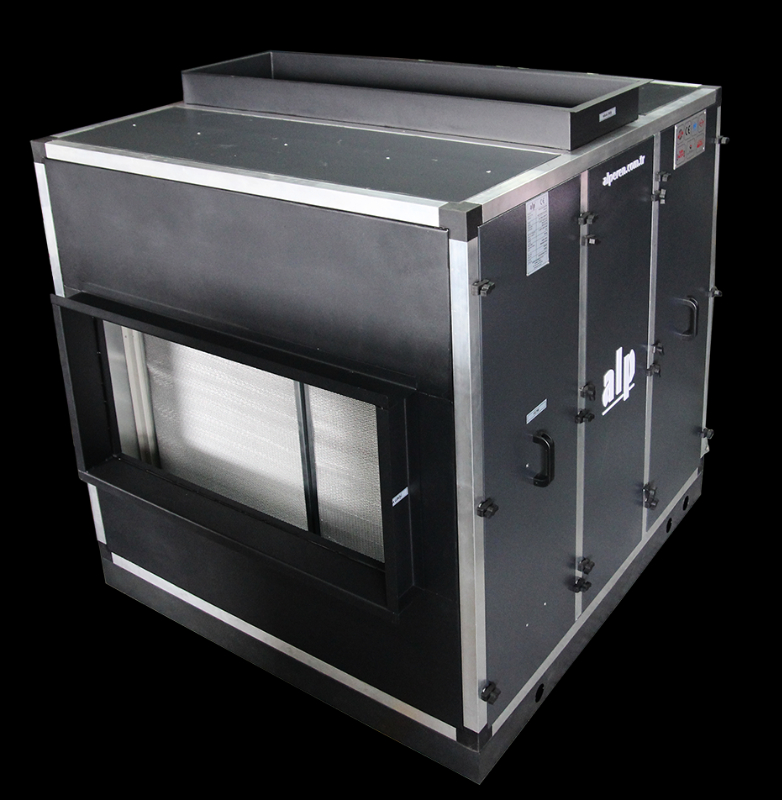

“Alp Concrete Cooling Systems” utilized to cool the concrete in special norms in industrial constructions such as dams, bridges and power plants is a system that cools the concrete itself but not the mixing water of the concrete.

Polyethylene pipes selected according to the criteria of the concrete to be employed after the mold beams laid in the mold are placed in the mold. Polyethylene pipes are placed in the mold in accordance with the project prepared earlier. After pouring of the concrete molding is completed, the cold water obtained from the concrete cooling group is moved in the concrete by virtue of polyethylene pipes and cooling of the concrete is ensured within the calculated time.

The system is fully automated, can provide the desired temperature and flow values rate and can make reporting within desired intervals.

Flow and temperatures system in outgoing and return collectors can be adjusted measured and reported separately.

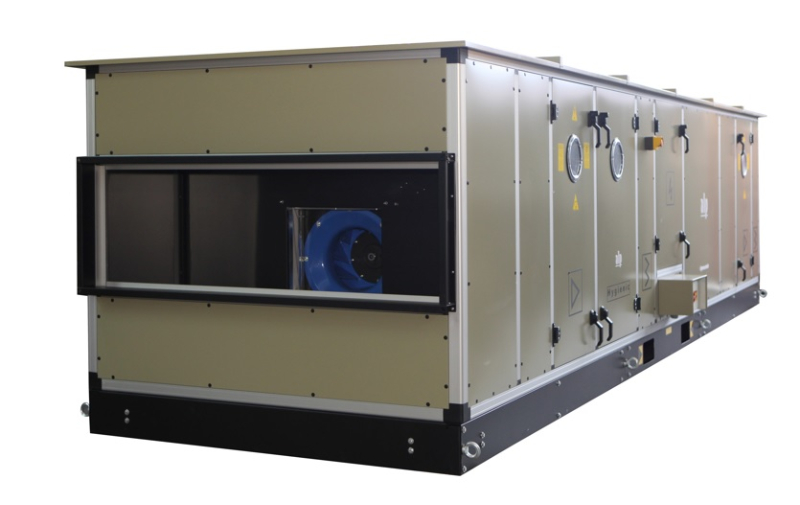

The system has been tested and received full marks in cooling of the concretes with special norms in the Bridge Project applied for the first time in our country.

Concrete cooling systems produced for Bridge Project have cold water delivery line as well as cold water return line. Each line in the outgoing collector can send water at the desired temperature and the desired flow rate separately. Operating ranges of the cooling group, delivery-return lines temperatures and flow rates are monitored and reported to the automation system.

Number of lines, the amount of heat, the amount of flow and operating ranges the delivery-return collectors of the concrete cooling system can be set at different values depending on your project.

“Alp Concrete Cooling Systems” designed through “Alperen Engineering” bear the signature of Turkish engineers. System design and automation have been designed, projected and manufactured through Turkish engineers.

The system has features to be utilized in different areas in need of cooling other than buildings and machinery such as cooling of facilities incident to race horses.