Product Details

Technicial Specifications

Other products

About the Company

Contact

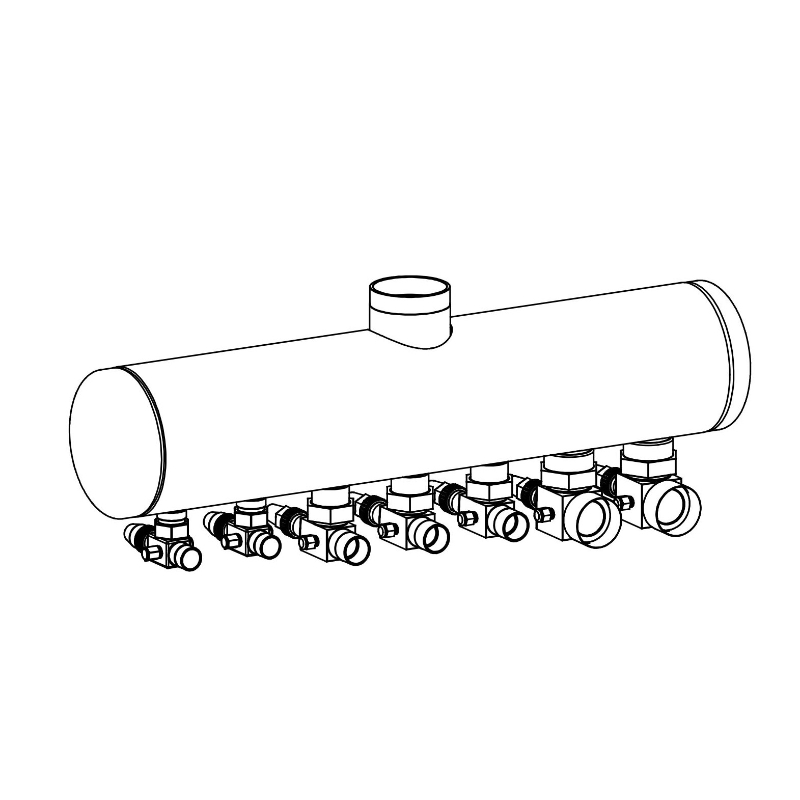

The task of high performance oil separators is to separate oil in the discharge refrigerant correctly and ensure oil return to the compressor most effectively. The purpose is to maintain crankcase oil level and increase the efficiency of the system by minimizing the excessive oil circulation. Glass fiber micro filter elements highly efficiently separate aerosol particles from the discharge gas flow. Thereby, the aerosol particles collide with borosilicate fibers and agglomer- ate into larger drops. The drops are drained to the bottom by gravity for oil return. Coalescent oil separators also separate solid particles from the discharge gas/oil. However, coalescent oil separators should not be used to clean refrigeration systems. A continuous increase of the pressure drop shows that coalescence element is dirty. It is recommended to change the filter when pressure drop increases.

High performance oil separators type are designed for using in various systems and multiple compressors for maximum energy-efficiency and low pressure oil management systems. They are suitable for scroll and piston compressors but they are not recommended for screw and rotary com- pressors. They minimize the amount of oil in the evaporator, improve heat transfer efficiency and reduce compressor running time. Standard product series are designed for use with subcritical CO2 applications.High performance oil separators type are the products with float system. It is protected against the pressure and circulation which may occur inside the product. Any contamination which may occur in the system can be easily caught by magnet in float system at oil outlet, thus it en- sures that valve operates in cleaner environment.