The valves of 30000, 30100 and 30200 series are two-way normally closed valves. Depending on the model they are direct action or servo-controlled diaphragm solenoid valves with SAE FLARE connections or weldable copper pipes All the coils are class h with winding made of enam- eled copper wire with insulation class 180°C. The outer casing and the reel are made of resin with dielectric properties that provide an effective waterproof insulation. The coil is always provided with two O-rings at the upper and lower ends that protect the device from humidity. Coils are designed for continuous operation.

APPLICATION

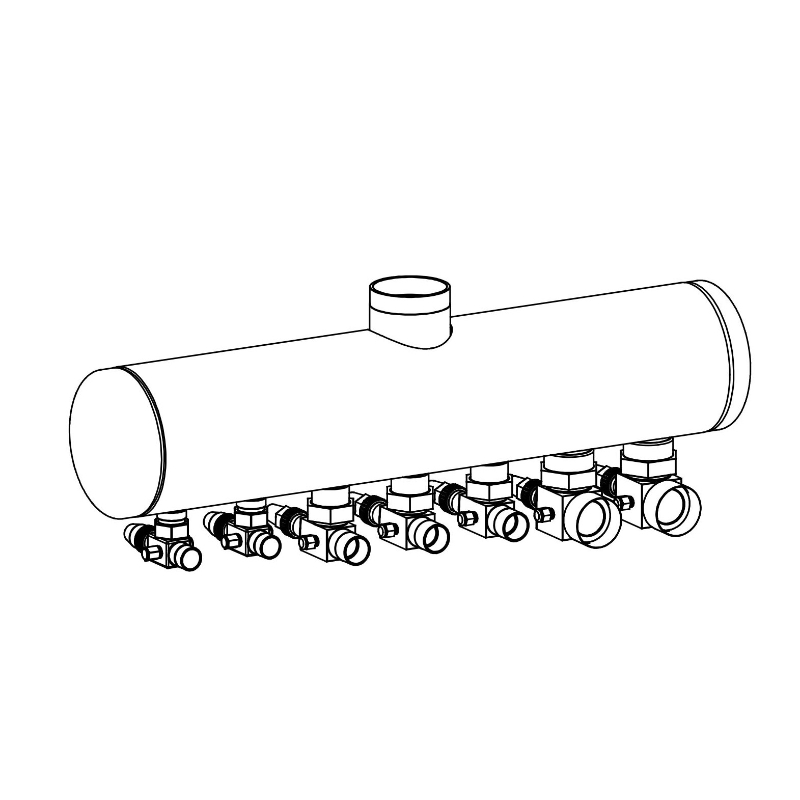

The solenoid valves illustrated in this chapter are designed for installation on commercial, industrial refrig- eration systems and air conditioning plants such as heat pumps, split units, cold rooms, rack systems, chillers etc applications

Suitable refrigerants:

• HCFC (R22)

• HFC (R134a, R404A, R407C, R410A, R507)

• HFO and HFO/HFC mixtures (R1234ze, R448A, R449A, R450A and R452A)

For specific applications with refrigerant fluids not listed above, please contact GVN technical department.

ADVANTAGES

All OLAB solenoid valves in the 30000 series feature the following qualitative advantages resulting from the use of our technology:

* HIGHLY ROBUST, the thickness of the sleeve obtained from AISI 303 stainless steel machined solid bar is greater than that of traditional tubes obtained from thin metal sheet

* 100% SAFE, approved IP67 UL “INTERNATIONAL PROTECTION” rating

* 100% TESTED, each valve bears the date and serial number proving that it has passed the test and allowing traceability of the performance data measured during testing over time.