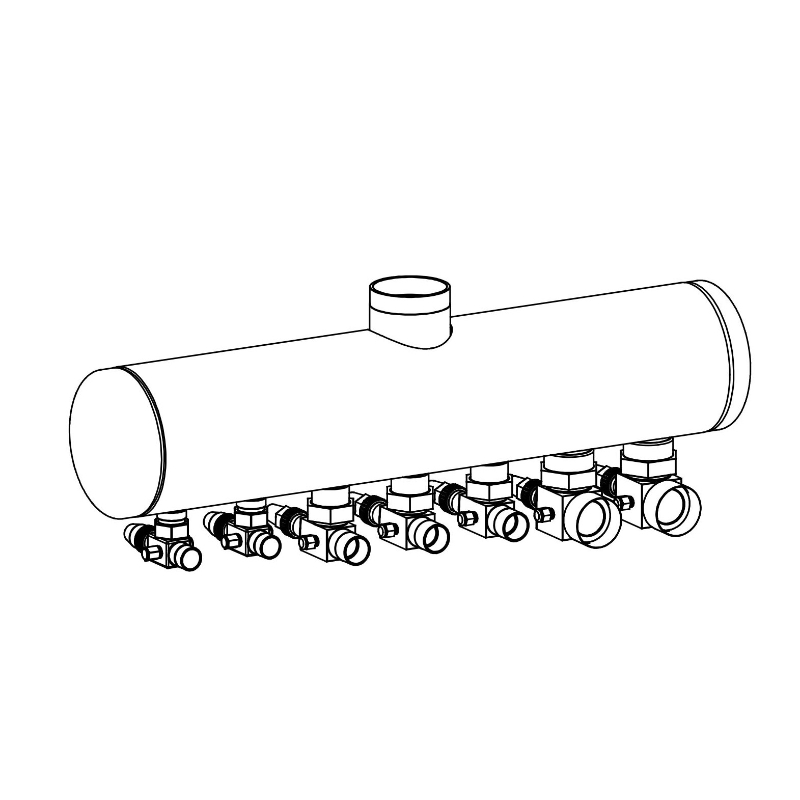

Shell and Tube Condenser

Product Details

Technicial Specifications

Other products

About the Company

Contact

Shell&Tube Condensers are used in industrial and comfort cooling units. G-RKMDEW and G-RKDEW series Shell&Tube Condensers are manufactured in order to provide low pres- sure loss and high efficiency starting from a cooling capacity of 20 kW up to a capacity of 1680 kW under standard working conditions. G-RKDEW series Shell&Tube condensers are used in cooling applications where city water and storage water are used while G-RKMDEW series Shell&Tube condensers are used in cooling applications with sea water.

DESIGN AND MATERIAL

Shell&Tube Condensers are designed in order to minimize performance decreasing factors such as vibration and corro- sion. G-RKMDEW series Shell&Tube condensers are designed and manufactured as resistant to corrosive effects of sea water. Materials used in Shell&Tube Condensers are selected according to “European Pressure Vessel Codes”. Materials used in shell&tube type evaporators are chosen in complience with “European Pressure Vessel Codes”

RKDEW Shell&Tube Condensers;

• Heat transfer pipes with a special geometry and inside and outside grooves enabling the heat transfer are made of copper

• Tube sheets and bodies are made of steel

• Head Covers are made of cast iron

• Bolts are made of steel alloy

• Gaskets are made of asbestos free materials that are com- patible with HCFC and HCF cooling gases.

QUALITY AND TEST

Mechanical calculations of GVN Shell&Tube Condensers are made in accordance with TS EN13445-3 standard and with a CE certificate in compliance with ISO 9001:2008 Quality Manage- ment System.

Shell&Tube Condensers are assessed through a nitrogen test with a gas side of 30 bars and a water side of 12 bars.

FOULING FACTOR

Fouling factor (f.f.) is important in selecting an evaporator. The fouling factor levels under certain conditions are given below.

• Closed-circuit mains water f.f.= 0.000043 m2K/W

• Open-circuit mains water f.f.= 0.000086 m2K/W

• Glycol solution < %40 f.f.= 0.000086 m2K/W

• Glycol solution > %40 f.f.= 0.000172 m2K/W

GÜVEN SOĞUTMA ÜNİTELERİ SAN. VE TİC. A.Ş.

Güven Soğutma is a family company, founded in Istanbul in 1985.

Our company developed itself rapidly in both domestic and international market with the production of pressure vessels & refrigeration equipment for industrial refrigeration and air conditioning sector and today became a leading company in Turkey in its product line.

Güven Soğutma has proven its quality with ISO 9001: 2015 standards and CE (PED) certification and became one of the world’s leading brands exporting to more than 60 countries by participating in many local and international exhibitions.

Today we are proud of serving better and being solution partners of our customers with our long-term based experience, new production areas and high technology machinery parks, effective staff, a wide range of high quality products, new generation Carbon Dioxide (CO2), Ammonia (NH3), R290 Propane products and our European business partners.