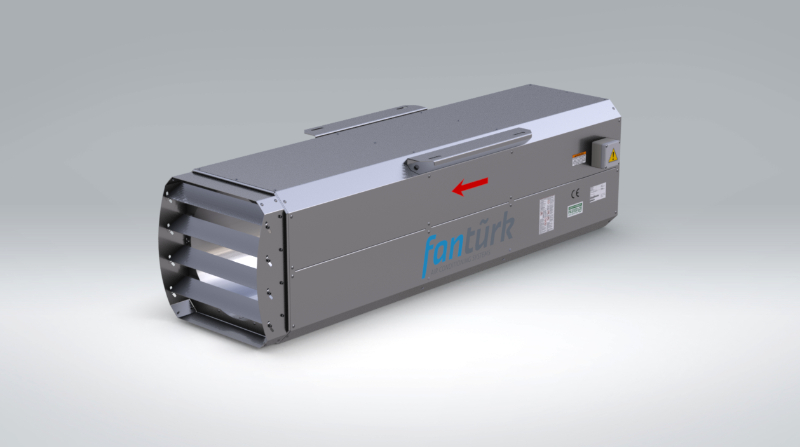

- The entire product is made of S235 quality sheet metal. It is coated with epoxy paint against corrosion. Fans are radial fans with backward curved blades. Motors are threephase and have 4 pole, IP55 and Class F insulation. Frequency control can be provided optionally. It is ready for duct installation.

Product Details

Technicial Specifications

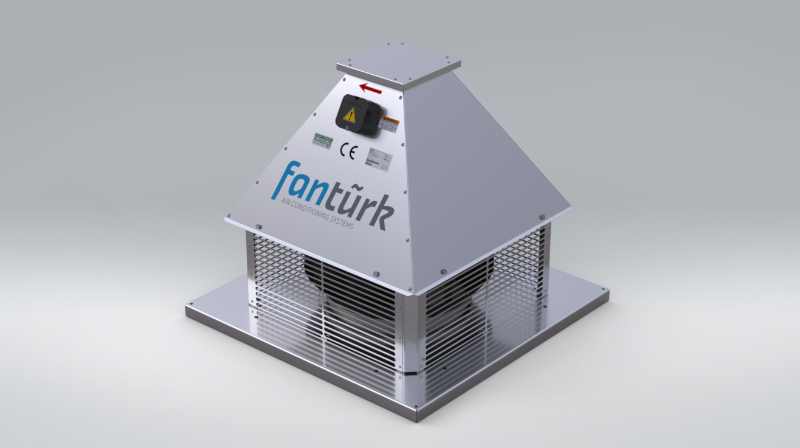

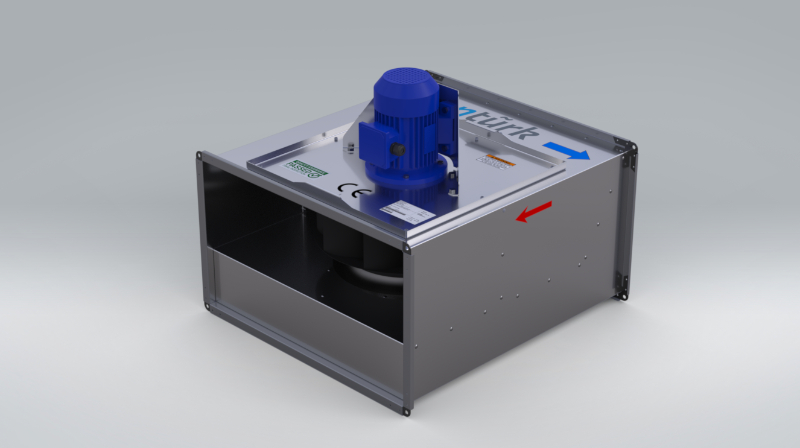

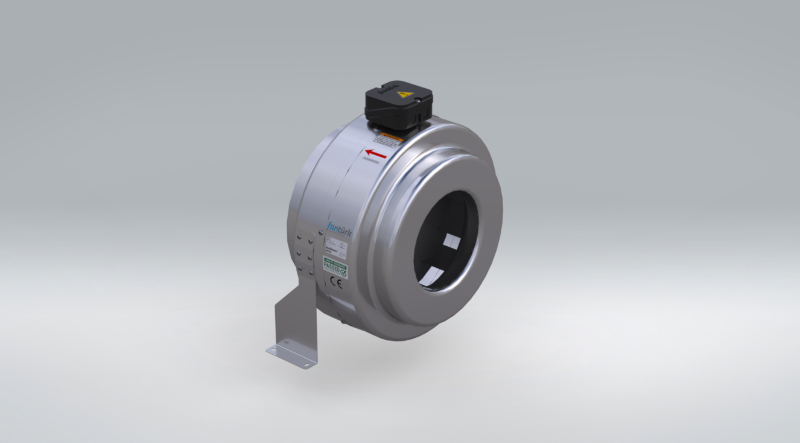

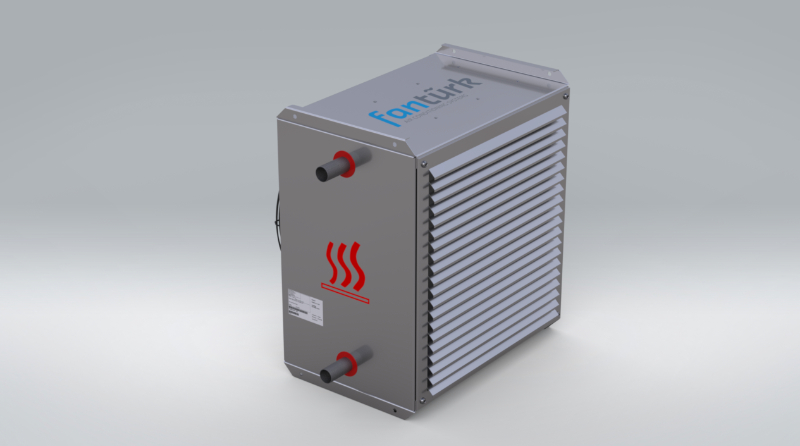

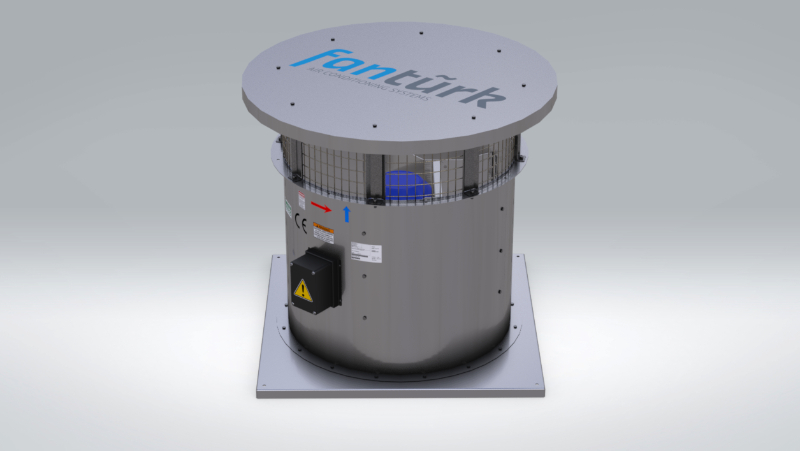

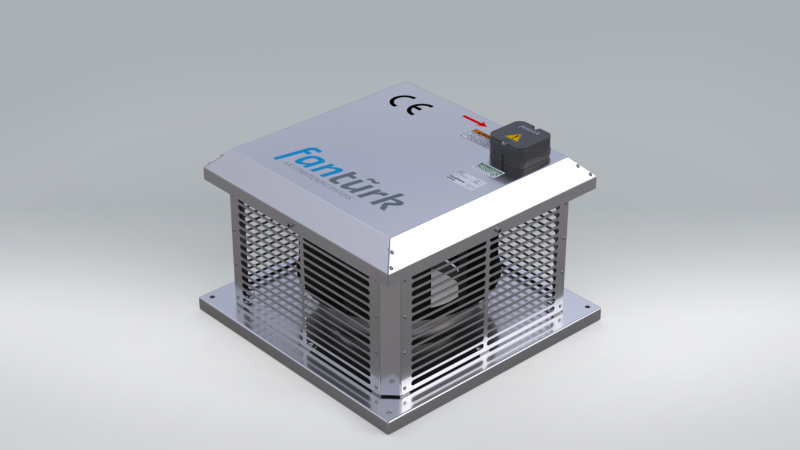

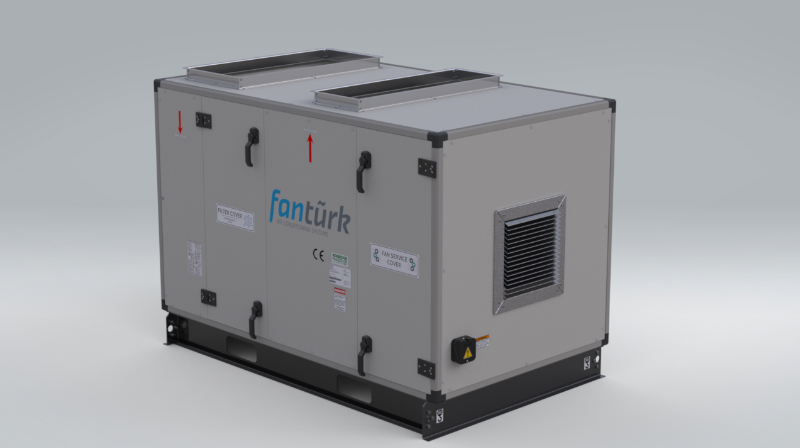

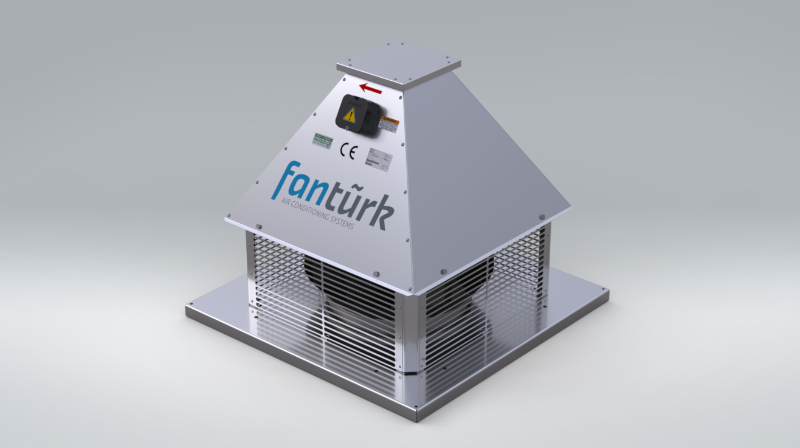

Other products

About the Company

Contact

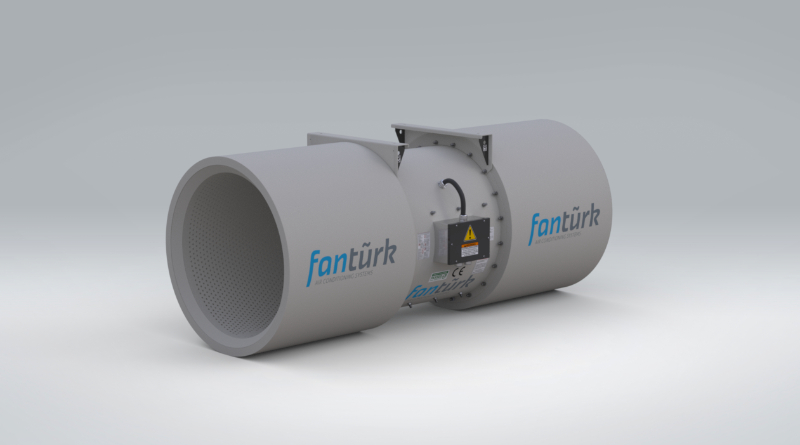

ABF Low Pressure Snail Fan is manufactured from high quality corrosion resistant S355 steel and coated with epoxy paint. The fans are radial fans with backward curved blades. It is possible to manufacture the drive system with Belt Pulley, direct coupled or elastic coupling. The temperature of the suctioned fluid should not be higher than 80°C. For higher temperatures, it is necessary to make modifications in the manufacture of the fan. Manufacturing with ExProof is possible. It can also be manufactured from stainless steel sheet for corrosive and high temperature working conditions. The ABF series is the ideal choice for high performance and trouble-free operation. It can be used in clean and slightly dusty fluid suction, cooling, ventilation, drying, mechanical extraction and toxic gas exhaust.

Snail Fans, which are used as indispensable devices of ventilation systems, are the most suitable devices to meet the need for ventilation in systems with high flow rates and high pressure losses at the same time. It is heavily preferred in heating, cooling systems, dust, sawdust suction lines, ambient ventilation and industrial applications. Snail Fans, produced with Fantürk quality, are selected among various models, the most suitable for the desired operating point in the systems.

These fans provide a very efficient operation due to the snail form in their case structure. This form has a positive effect on efficiency, energy saving and desired flow values in the operating device. This is the reason why especially volute fans are chosen in heavy industry and industrial applications. As Fantürk, in addition to choosing the most suitable snail fan to work at the working points requested by our customers from our standard models, we can also make special designs and manufacture for special applications.

High Temperature or Ex-Proof Feature is one of the remarkable features of volute fans. The produced volute fans are produced in accordance with the maximum continuous operation at 120°C. This resistance can be increased to 200°C temperature ranges by taking different precautions in the volute body and motor drive type. In addition, production with Ex-Proof feature is possible upon request.

As a Motor-Rotor Connection, Fantürk Snail Fans are produced with direct coupled drive as standard. However, a belt-pulley or coupling drive system can be applied in line with the customer’s request. The throw direction of the snail fans produced thanks to its ergonomic design can be adjusted as desired. Moreover, Optional Slide System application is available. Sliding system application can be made upon request. In this system, a slide is placed under the motor stand, and the motor stand and rotor can be removed without interfering with the fan body during maintenance and cleaning, and necessary actions can be taken.

ABF Low Pressure Snail Fan Technical Specifications

ABF series are single inlet high efficiency and low noise volute fans. The maximum temperature of the fluid being sucked should be 120°C. Fan manufacture requires modifications for higher temperature operation. The body is made of S235 steel and all surfaces are coated with epoxy paint resistant to corrosion. Can be made of stainless steel for corrosive and high temperature environments. Fan drive can be belt-sourced, directly coupled or coupled system.

Optionally, it can be manufactured with Ex-Proof feature. It is suitable for use in fresh air or light dusty air intakes, in all kinds of ventilation systems with ventilation, drying, mechanical extraction, toxic gas systems. The snail fan throw position must be specified when ordering. In order to determine the firing position, the most suitable model option is selected when looking from the engine side.

ABF Low Pressure Snail Fan Models

ABF 250/0,25 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,25 kW

- Cycle 1360 d/d

- Noise Level 64 dBA

- Weight 49 kg

ABF 250/0,37 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,37 kW

- Cycle 1360 d/d

- Noise Level 65 dBA

- Weight 50 kg

ABF 250/2,2 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 2 kW

- Cycle 2850 d/d

- Noise Level 77 dBA

- Weight 58 kg

ABF 250/3 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 3 kW

- Cycle 2900 d/d

- Noise Level 78 dBA

- Weight 63 kg

ABF 280/0,55 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,55 kW

- Cycle 1370 d/d

- Noise Level 67 dBA

- Weight 63 kg

ABF 280/4 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 4 kW

- Cycle 2900 d/d

- Noise Level 79 dBA

- Weight 76 kg

ABF 280/5,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 2 kW

- Cycle 2900 d/d

- Noise Level 82 dBA

- Weight 93 kg

ABF 315/1,1 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 1,1 kW

- Cycle 1390 d/d

- Noise Level 70 dBA

- Weight 84 kg

ABF 315/7,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 7,5 kW

- Cycle 2900 d/d

- Noise Level 84 dBA

- Weight 114 kg

ABF 315/11 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 11 kW

- Cycle 2930 d/d

- Noise Level 85 dBA

- Weight 143 kg

ABF 355/0,37 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,37 kW

- Cycle 930 d/d

- Noise Level 60 dBA

- Weight 95 kg

ABF 355/0,55 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 0,55 kW

- Cycle 930 d/d

- Noise Level 62 dBA

- Weight 98 kg

ABF 355/2,2 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 2,2 kW

- Cycle 1420 d/d

- Noise Level 72 dBA

- Weight 106 kg

ABF 355/15 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 15 kW

- Cycle 2935 d/d

- Noise Level 79 dBA

- Weight 166 kg

ABF 355/18,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 18,5 kW

- Cycle 2935 d/d

- Noise Level 82 dBA

- Weight 177 kg

ABF 400/1,1 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 1,1 kW

- Cycle 930 d/d

- Noise Level 65 dBA

- Weight 114 kg

ABF 400/4 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 4 kW

- Cycle 1430 d/d

- Noise Level 73 dBA

- Weight 135 kg

ABF 450/2,2 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 2,2 kW

- Cycle 950 d/d

- Noise Level 68 dBA

- Weight 167 kg

ABF 450/5,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 5,5 kW

- Cycle 1440 d/d

- Noise Level 75 dBA

- Weight 182 kg

ABF 450/7,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 7,5 kW

- Cycle 1450 d/d

- Noise Level 76 dBA

- Weight 194 kg

ABF 500/4 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 4 kW

- Cycle 960 d/d

- Noise Level 71 dBA

- Weight 240 kg

ABF 500/11 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 11 kW

- Cycle 1460 d/d

- Noise Level 78 dBA

- Weight 290 kg

ABF 500/15 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 15 kW

- Cycle 1460 d/d

- Noise Level 79 dBA

- Weight 300 kg

ABF 560/5,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 5,5 kW

- Cycle 950 d/d

- Noise Level 74 dBA

- Weight 360 kg

ABF 560/7,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 7,5 kW

- Cycle 960 d/d

- Noise Level 75 dBA

- Weight 395 kg

ABF 560/18,5 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 18,5 kW

- Cycle 1460 d/d

- Noise Level 82 dBA

- Weight 479 kg

ABF 560/22 Model

- Voltage 380 V

- Frequency 50 Hz

- Power 22 kW

- Cycle 1460 d/d

- Noise Level 83 dBA

- Weight 490 kg