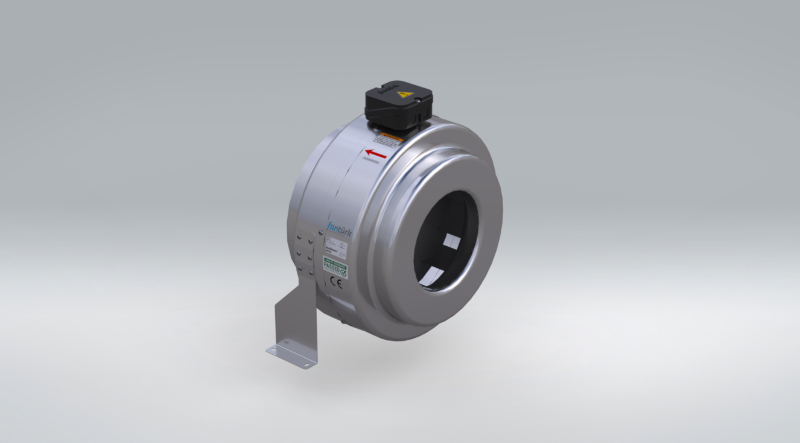

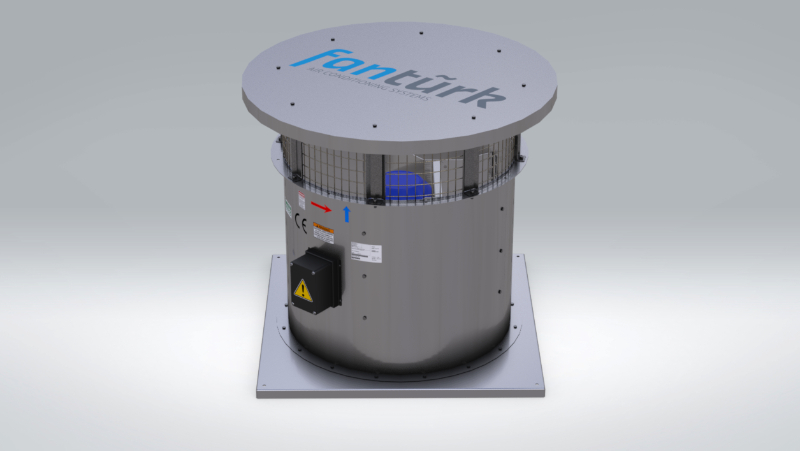

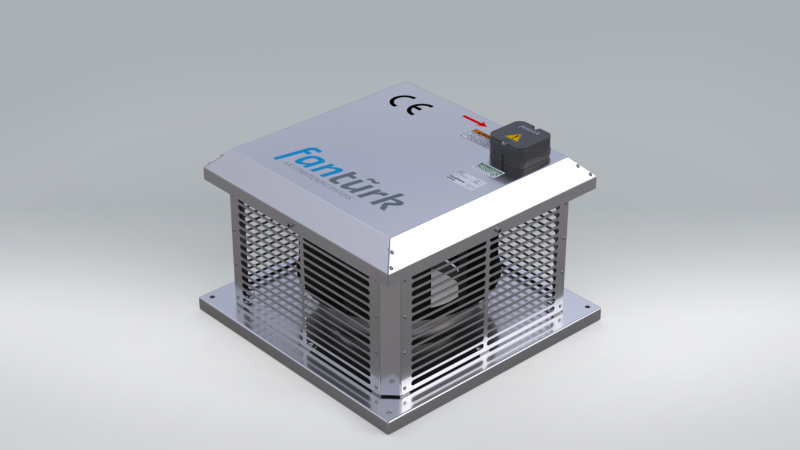

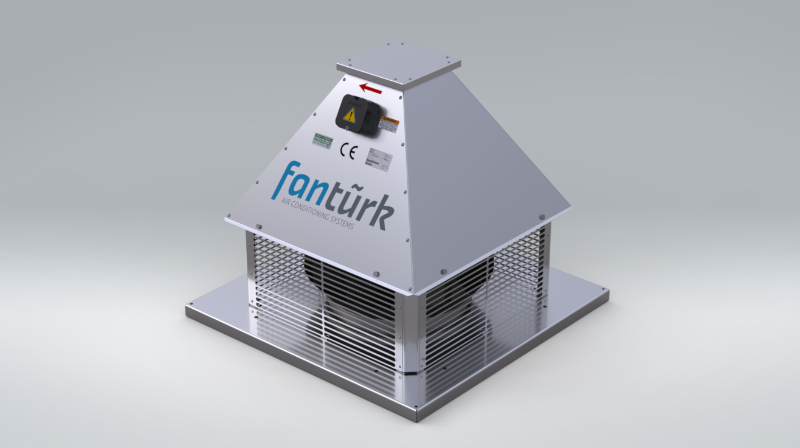

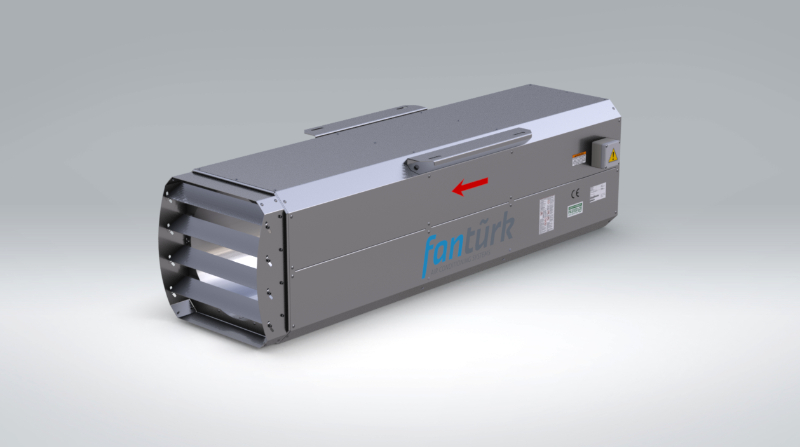

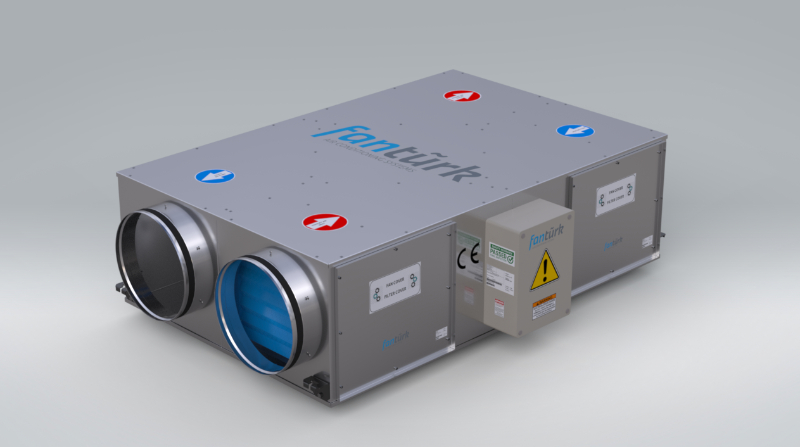

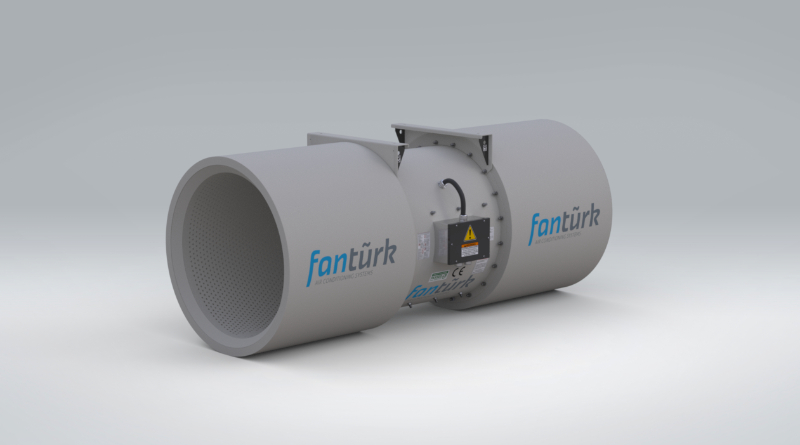

- J-FWA Axial Jet Fan is manufactured from high quality corrosion resistant galvanized steel. The blade angles of the propellers used are adjustable and manufactured from special alloy aluminum. The products produced have been tested in international accredited institutions according to the EN 12101-3 Standard and are fire-certified as resistant to working at 400°C for 2 hours. It is manufactured between Ø315mm and Ø630mm diameters. According to the project used, there are two-way, one-way, double-speed, single-speed options.

- Body is manufactured from high quality galvanised sheet. All equipment used is suitable for operation in case of fire. The product is F300/2h certified by internationally accredited organizations. (EN 12101-3)

- The motor is three-phase and double-speed and is IP55 and Class H insulated. The propeller is of an adjustable angle type and is made of special alloyed aluminum. There is a silencer in the suction and blow section

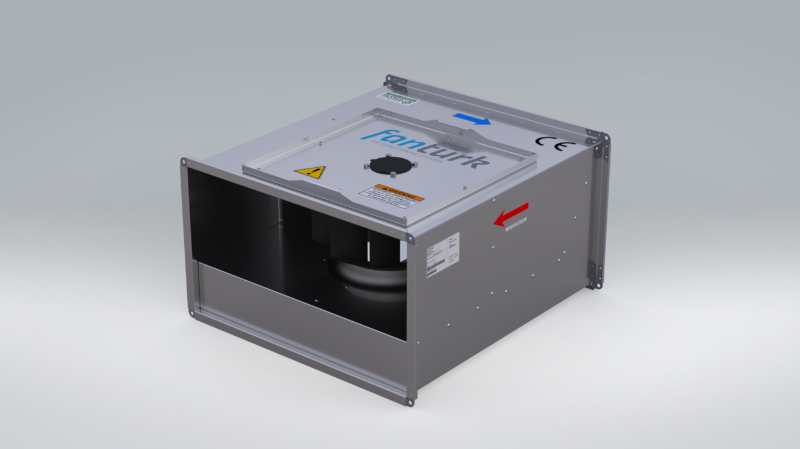

- J-FWA series is the ideal choice for high performance and trouble-free operation. It is suitable for use in all kinds of hotels, hospitals, residences, shopping malls, offices, residential parking lots ventilation systems. Thanks to its unique skid system design, disassembly and maintenance times are minimized with an easy intervention to the engine. Jet Fan systems, which we see in the indoor car parks of shopping malls, large hospitals and hotels, provide the evacuation of harmful gases such as exhaust gases from vehicles in the car park and daily ventilation of the car park. In addition, it also provides protection against possible dangers by having features such as the evacuation of smoke released in the event of a fire. Jet fan systems in car park ventilation are divided into two as Radial Jet Fans and Axial Jet Fans.

- Axial jet fans are used in parking lots. A healthy ventilation of indoor parking lots is one of the biggest problems. Axial jet fan is one of the most suitable devices to solve this problem. Produced with Fantürk quality, Axyal Jet Fan is a product that has successfully passed all tests of internationally accredited organizations and is resistant to working at temperatures up to 400 degrees. There are two-way and one-way options, as well as double-speed and single-speed options, it can be preferred according to the characteristics of the area to be used.

Product Details

Technicial Specifications

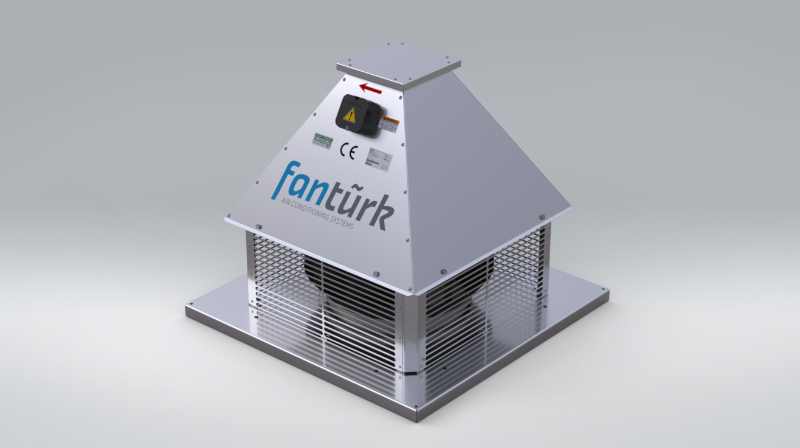

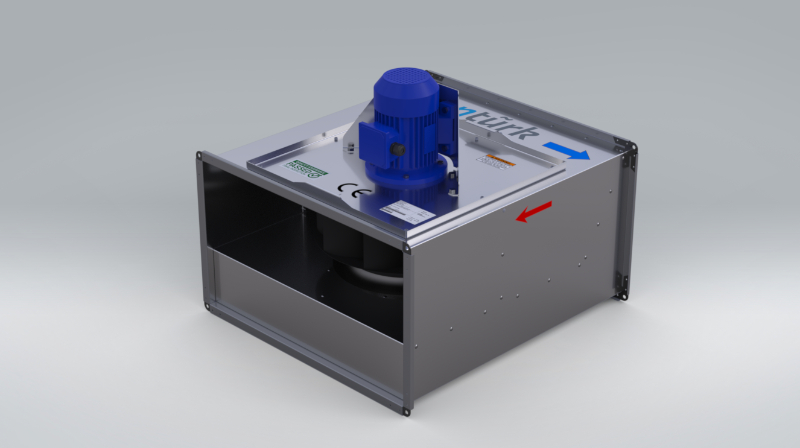

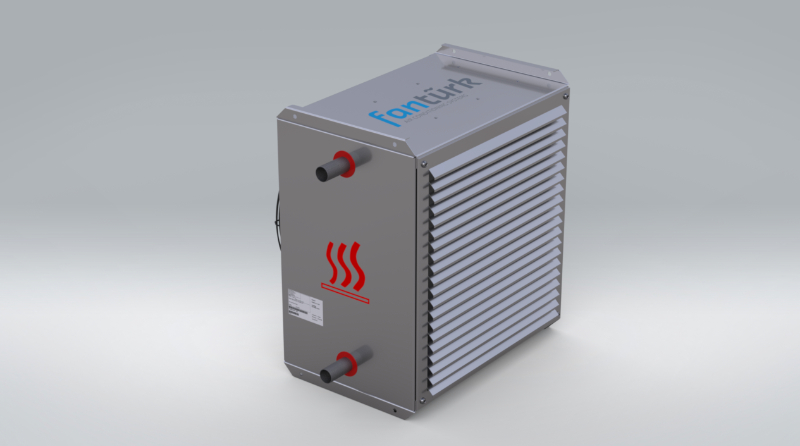

Other products

About the Company

Contact

1-Fan Body

Propellers used in J-FWA Axial Jet Fan Models are made of ST 52 steel blades or body and blades with adjustable blade angles are made of special alloy aluminum. According to the project, it can operate with the same performance in both blowing directions, thanks to its reversible blade structure. Conforms to international standards.

2-Propeller

It is manufactured as a standard (380 V – 50 Hz) or on request in accordance with other voltages and frequencies (400 / 415/ 440 V – 50 Hz). As standard, Class H, S1+S2, IP55, resistant to 400 degrees for 2 hours or to 300 degrees for 2 hours, single speed or double speed motor is used.

3-Electric Motor

In these series, the sound intensity increases due to the high air outlet velocities and for this reason, jet fans are used with silencer as standard.

4-Slide System

Thanks to the specially designed skid system in J-FWA Models, easy intervention is provided to the engine and disassembly and maintenance times are minimized. Thanks to its special design, the engine can be easily accessed, the engine can be disassembled and reassembled. A sliding system was used in the design. All national and international certificates of the product are complete. All these features are produced on the basis of international standards.

5-Adjustable Propeller Angle

Axial Jet Fan is made of high quality galvanized sheet that has passed the highest durability tests. The propellers are adjustable in angle and produced from special aluminum alloy material. The sound intensity is high due to the very high air velocity during operation, therefore there is a silencer on the suction and discharge sides of the product.

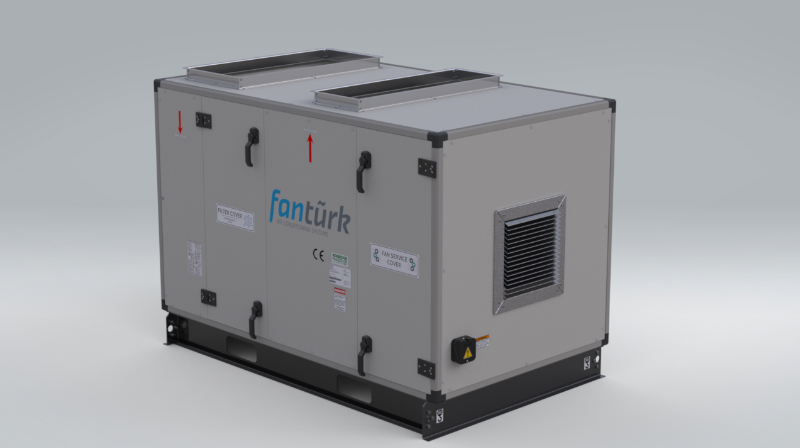

6-Energy Saving with Automation System

Thanks to the integrated Fantürk Jet Fan Automation, it works fully equipped against all possible bad scenarios and prevents dangers in the area where it is used. It can evacuate smoke in the fastest way in case of fire. In addition, thanks to this automation, the fan works according to the information coming from the sensors that measure the carbon monoxide rate in the environment, thus providing significant energy savings.