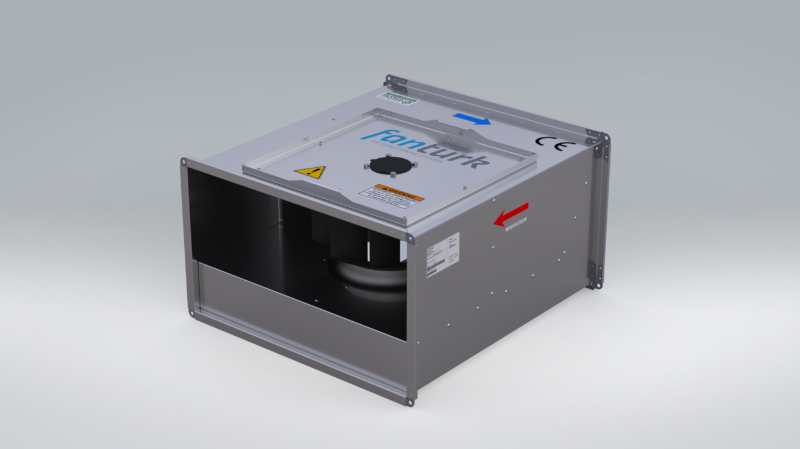

- Body is manufactured from high quality galvanised sheet.

- All equipment used is suitable for operation in case of fire.

- The product is F300/2h certified by internationally accredited organizations.

- (EN 12101-3)

- The motor is three-phase and double-speed and is IP55 and Class H insulated.

- Fans are radial fans with backward curved blades.

Product Details

Technicial Specifications

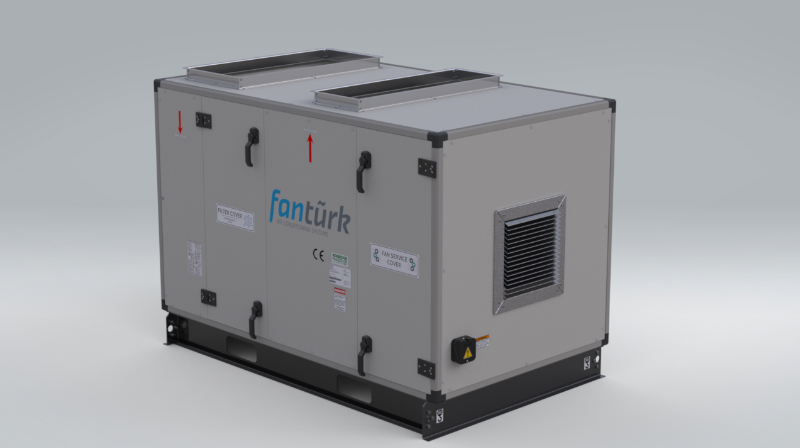

Other products

About the Company

Contact

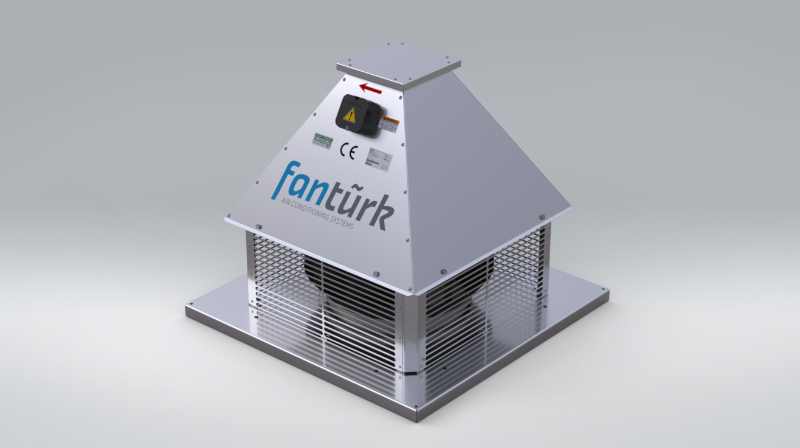

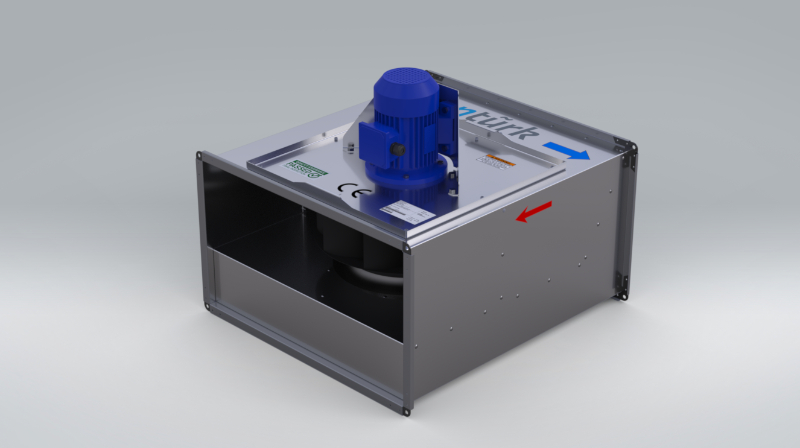

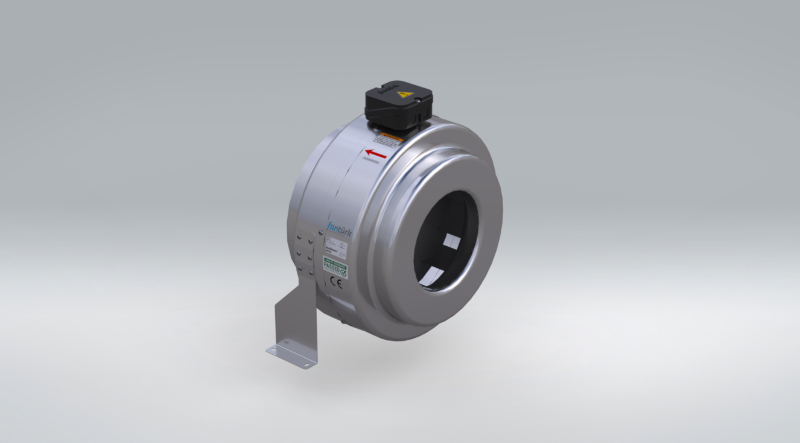

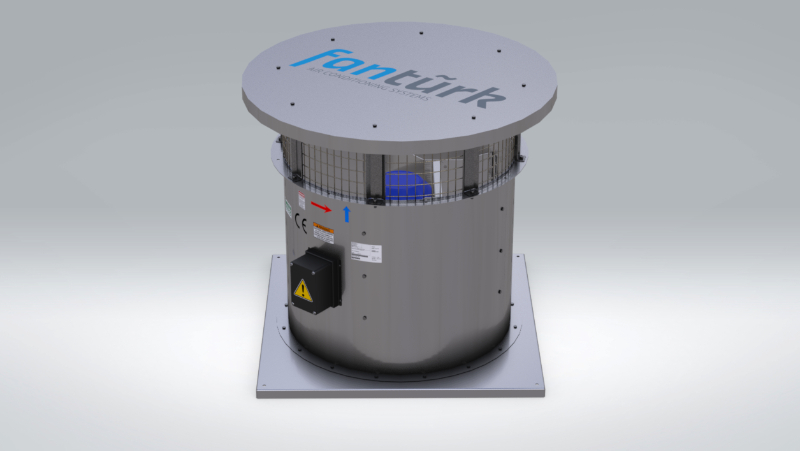

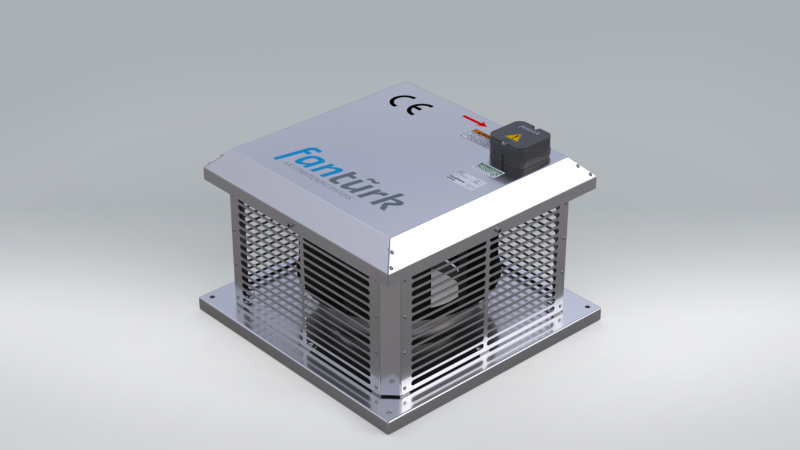

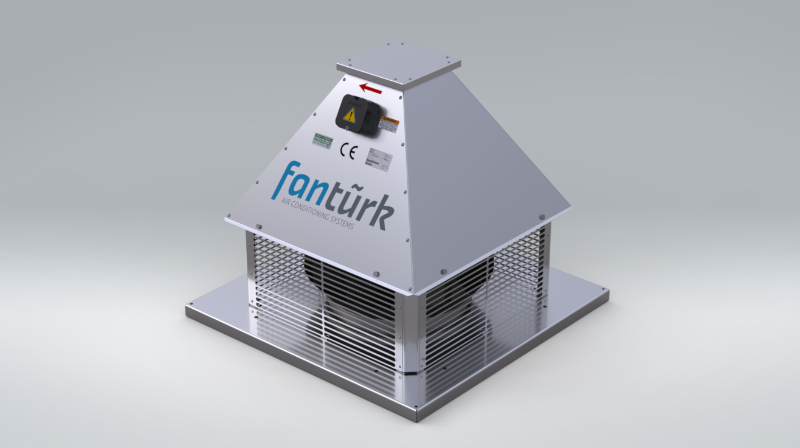

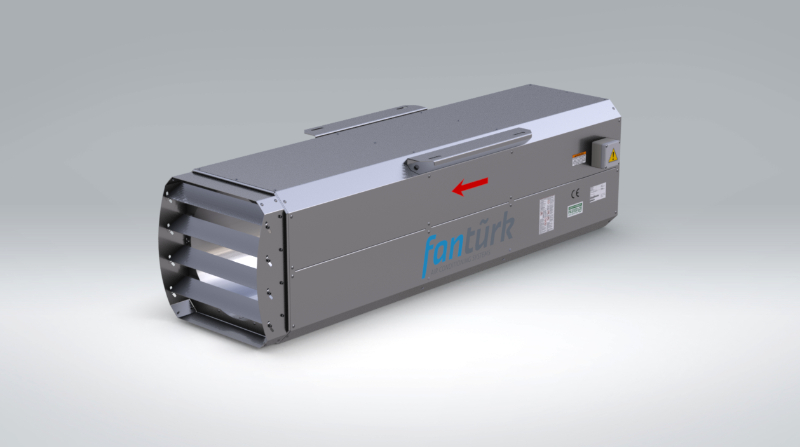

R-FWA Radial Jet Fan is manufactured from high quality corrosion resistant galvanized steel. The fans are radial fans with backward curved sparse blades. The products produced have been tested in international accredited institutions according to the EN 12101-3 Standard and are fire-certified as resistant to working at 300°C for 2 hours. There are double-speed or single-speed options depending on the project used. The R-FWA series is the ideal choice for high performance and trouble-free operation. Thanks to its compact design, it is suitable for use in all kinds of hotels, hospitals, residences, shopping malls, offices, residential parking lots ventilation systems with low ceiling heights.

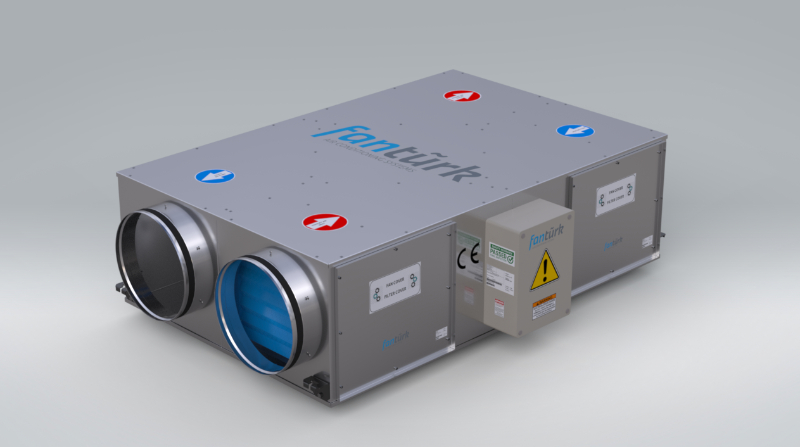

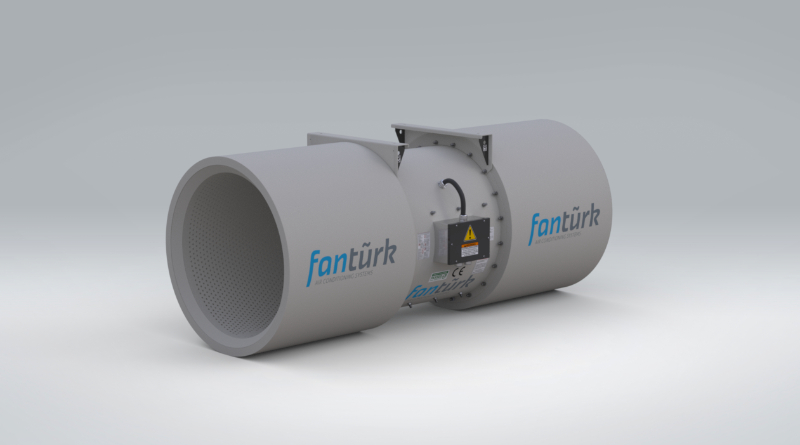

Jet Fan systems, which we see in the indoor car parks of shopping malls, giant health institutions and hotels, ensure the evacuation of harmful gases such as exhaust gases from vehicles in the car park and daily ventilation of the car park. In addition, it also provides protection against possible dangers by having features such as the evacuation of smoke released in the event of a fire. Jet fan systems in car park ventilation are divided into two as Radial Jet Fans and Axial Jet Fans.

Radial jet fans are generally used in parking lots. A healthy ventilation of indoor parking lots is one of the biggest problems. Radial jet fan is one of the most suitable devices to solve this problem. Radial Jet Fan, produced with the quality of Fantürk, has successfully passed all the tests of internationally accredited organizations and is a product resistant to working at temperatures up to 400 degrees. Double-speed and single-speed options are available, it can be preferred according to the characteristics of the area to be used.

The reason why Radial Jet Fans are preferred is that, thanks to their compact structure, they can be used in car parks with low ceiling heights without hindering the height. The motors used in the devices have a pad-mounted connection type and are connected to the rotor from the inside, providing gain in height. Thus, the height of the device has been reduced and it can be easily used in closed car parks with low ceiling heights.

Energy Saving comes to the forefront with the Automation System. Thanks to the integrated Fantürk Jet Fan Automation, it works fully equipped against all possible bad scenarios and prevents dangers in the area where it is used. It can evacuate smoke in the fastest way in case of fire. In addition, thanks to this automation, the fan works according to the information coming from the sensors that measure the carbon monoxide rate in the environment, providing significant energy savings. Radial Jet Fan, produced with the quality of Fantürk, is a product that has passed all the tests of institutions with international quality and assurance authority, and is suitable for working at high temperatures.

R-FWA Radial Jet Fan Technical Specifications

R-FWA Radial Jet Fan models equipment are certified to EN 12101-3 300 degrees for 2 hours, from internationally recognized accreditation organizations. The body of R-FWA Radial Jet Fan models is manufactured from high quality galvanized steel. The radial induction fan in the compact designed case is made of S235 quality steel.

It is manufactured as a standard (380 V – 50 Hz) or on request in accordance with other voltages and frequencies (400 / 415/ 440 V – 50 Hz). As a standard, Class H, S1+S2, IP55, single-speed or double-speed motors with resistance to 400 degrees for 2 hours are used. Pad mounted special connection type is used in motor connection. It is suitable for use in car park ventilation systems with low ceiling heights.

Jet fan parking lot ventilation projects should be supported by computational fluid dynamics analysis. CFD (HAD) analyzes to be carried out are very important in terms of the accuracy of the project work, the precise determination of jet fan placements, and the control of the position of the exhaust and fresh air shafts. The analysis to be made should be prepared with the fire simulation and boundary conditions prepared in accordance with the BS 7346-7 standard after the 3D modeling of the relevant car park. The condition of the parking lot in case of a possible fire or in the evacuation of the exhaust gases formed in the building is analyzed as a result of the analysis with this simulation. In this way, preliminary information about how the air flow and smoke extraction will behave in the real situation is obtained.

These analyzes should be performed using CFX, Flow Simulation, PyroSim or similar internationally recognized software. According to the simulation result, the number and placement of jet fans should be optimized. Smoke density at a height of 1.7m from the ground, visibility and air movements, temperature distribution in the parking lot at the time of fire, air flow details and air velocity profiles that will occur in the parking lot are examined. To summarize, Smoke Analysis, Visibility Analysis, Air Velocity Analysis and Temperature Analysis are performed. Moreover, these analyzes are examined according to ASHRAE, BS 7346-7, NFPA 130 standards.